Why Choose PHB as Your Aluminum Die Casting Manufacturer?

- From design concept to production and packaging, PHB is a global aluminum die casting manufacturer with clients ranging from automobile manufacturers to the U.S. military and beyond.

- PHB solves problems. Our clients value our ability to turn complex design specifications into reality.

- PHB handles all aspects of aluminum die cast manufacturing, from mold design and testing to precision aluminum parts manufacturing, finishing, and packaging.

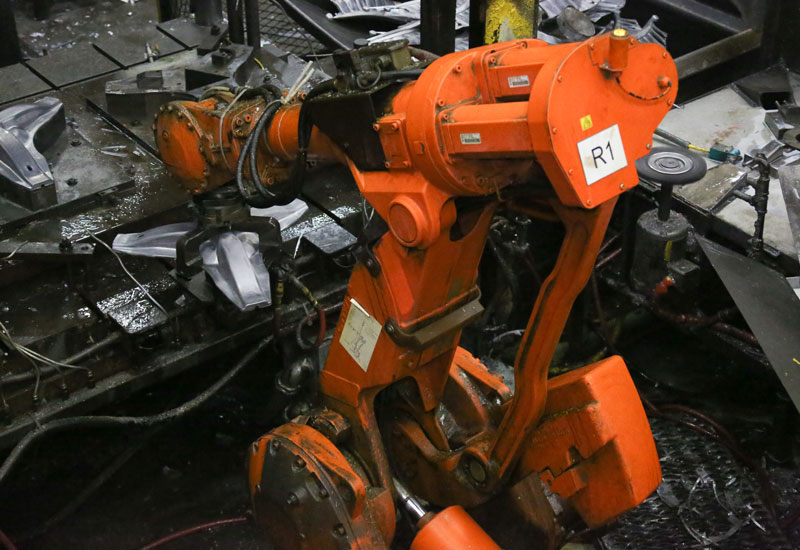

An Aluminum Die Casting Manufacturer & Precision Aluminum Parts Company

MagmaSoft® Aluminum Mold Flow Testing

PHB uses the internationally recognized MAGMAsoft® simulation technology to optimize tool design and aluminum casting quality. MAGMAsoft® simulation capabilities provide a better understanding of aluminum injection mold filling, high pressure aluminum die casting, solidification, mechanical properties, thermal stresses and distortions, and much more. Fully menu-driven with an integrated solid modeler, CASD interfaces, and extensive databases, MAGMAsoft® provides a complete solution for design, production, and quality departments. Read more on MAGMAsoft® and the aluminum die casting process.

Prototyping of Aluminum Parts

As an aluminum die casting manufacturer PHB can provide components and assemblies in prototyping and low-volume production quantities using a multitude of methods, including (but not limited to):

- Plaster Injection Mold Castings

- CNC Machining and Hog-outs

- Direct Metal Laser Sintering (DMLS)

- P-20 Tooling

Aluminum Alloy Die Casting

Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls. Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting.

- Aluminum: 360, 380, 383, 413, and A304 K-Alloy

- Zinc-Aluminum: ZA-8, ZA-12, and ZA-27

Aluminum Surface Finishing

PHB will manage customer finishing requirements to ensure parts meet specifications in both a timely and cost-effective manner.

- Powder Coating (electrostatic application)

- Wet Paint

- Chromate

- E-Coat

- Electroless Nickel

- Chrome

- Silk Screening and Stenciling

- EMI/RFI Shielding

- Surface Conditioning (shot and bead blasting)

CNC Machining & Other Services

In addition to our capabilities as an aluminum die casting manufacturer, PHB offers close-tolerance CNC machining including turning, milling, drilling, boring, and tapping capabilities. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Additionally, PHB provides a number of value-added services for our customers, saving them the time it takes to obtain multiple quotes and manage multiple suppliers. Our large facility and knowledgeable staff allow for high volume production and quick turnaround. With our testing and quality assurance processes, we ensure the highest quality products with the most cost-effective short-run production services.

Our Manufacturing Packaging Process

PHB offers a variety of packaging options for our customers. We can provide packaging layered or by cell. We cater to individual markets all across the globe, and understand that we may have to create something just for you. That’s why we also offer custom-designed returnable cardboard or plastic packaging.

the problem

A global leader in automotive lighting came to PHB with the challenge of creating two castings – one for low beams and one for high beams. Because of the complexity in aligning the fixtures (die cast heat sink pads) for the LEDs, prior designs had only allowed them to have three heat-sink pads per casting. Since both the low beams and high beams required six heat sinks, each headlight required four castings. The problem compounded when the mirror design was required for left or right headlights. With the added expense of creating separate tooling for all of the castings, and the additional time and expense involved in aiming these eight castings, our customer realized it was time for a new solution.

the solution

The challenge in producing the six heatsink pads was to maintain the profile tolerance of the 6 pads to within .4mm of the datum structure. There are 17 individual features at each pad location, or 102 total features per casting that are critical to function. Any missing feature results in a part that our customer cannot fully assemble. PHB utilized the MAGMA process simulation and other camera quality inspection, close tolerance machining, and precision quality control to develop and produce a two-casting headlight assembly for our customer.