Complete Die Casting Solution for Engineering, Prototyping, and Production

PHB Engineering is your Key to Die Casting Success

Die cast parts are the perfect choice for any OEM that needs to manufacture a high volume of complex parts with a long production lifespan. At PHB, we have been creating die castings for over 100 years. Our engineers are industry leading experts who can lend their wealth of experience and knowledge to your next project. We specialize in early involvement to improve part design for manufacturability. From conception to production, our world-class engineers touch every aspect of the manufacturing process to ensure your project goes off without a hitch. If you are seeking a complete die casting solution, PHB’s engineers are prepared to provide it.

Working with OEMs from Tooling Design to Die Cast Part Production

PHB’s engineers are focused on efficiency and will develop a complete die casting solution that is structured around optimum part manufacturability. Our most important goal is to foster a strong working relationship with every customer who contracts our team. From the beginning of each job, our project engineers work closely with our sales and estimating teams to learn everything we can about your needs, from the specifics of your part to your overall project goals. We can quickly review your part specifications and design requirements. Our engineers are well versed in taking early-stage drawings and concepts across the finish line. We will work with whatever drawings, models, or sample parts you have available and turn them into high quality die castings. We can even reverse-engineer your existing parts using state-of-the-art laser scanning. PHB engineers can assist you in transitioning your part from other manufacturing methods.

Offering Help with Material Selection, Post Die Casting Machining, and more

Using our decades of hands-on die casting experience, we will guide you to bring your part into alignment with NADCA standards. We can help you to select the best option for your project from our standard alloys. Our design recommendations will address potential problems and avoid manufacturing defects before they can occur. Our project engineers will use your part design specifications to determine any secondary operations required beyond casting. We offer many in-house operations including drilling and tapping, spot facing, vibratory deburring, shot blasting, leak testing, and maintain a complete in-house CNC machining division. PHB can also manage the supply chain for outside operations such as painting, powder coating, and plating. By considering all necessary operations at the earliest opportunity, we can give accurate quotations and meet all your expectations.

In-House Tooling Design and Local Toolmaking Support

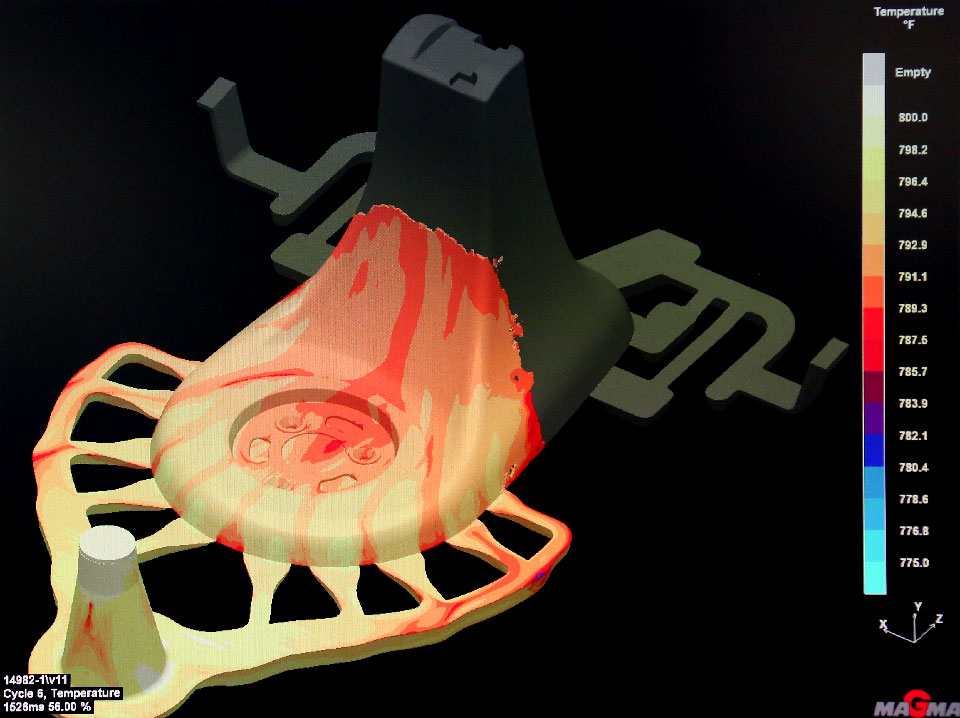

Once your part design has been finalized, we build a custom manufacturing solution for your project. This process begins with in-house die design in PTC Creo and mold flow analysis with MAGMAsoft®. Our manufacturing engineers utilize over 50 years of die design experience to make the most reliable and accurate tools in the industry. Using MAGMAsoft®, PHB engineers simulate the die casting process to optimize die filling, reduce solidification defects, and understand thermal distortion of the casting geometry. By analyzing this simulation, we can immediately validate and improve our designs.

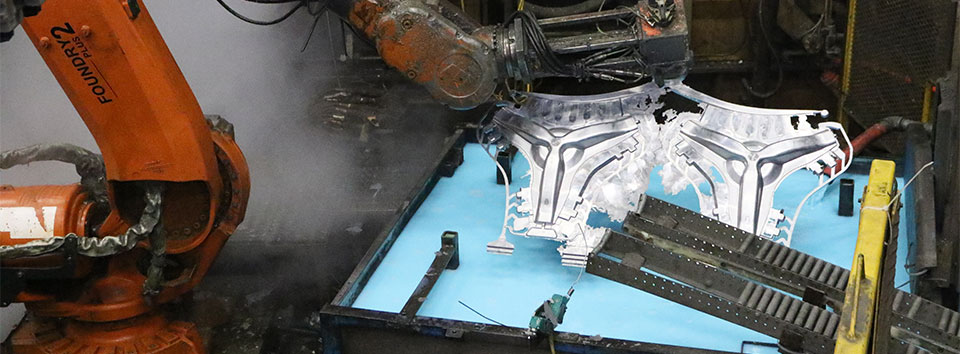

Once simulation work is complete, we iterate all casting parameters to devise the best die casting process for each part. Full dies are built locally at our sister company Reddog Industries where a full on-site tool room allows for quick turnaround for any die repairs and preventative maintenance. Our manufacturing engineers plan for every manufacturing operation, including in-house design for all fixtures and even automation solutions. PHB manufacturing engineers work closely with our quality engineers to troubleshoot, addressing any issues before they can become problems. This quality check process is a vital aspect in our ability to provide OEMS with a complete die casting solution that matches their precise specs and design expectations.

One-Stop Die Casting Shop Performing CNC Machining for Tight Tolerance Parts

Die casting offers a major advantage over other manufacturing methods because detailed, complex parts can be made at near net shape. Sometimes your part specifications may require features that require tolerances tighter than die casting alone can provide. In these scenarios, PHB has an on-site CNC Machining Division fully staffed with experienced engineers who can take your parts to the next level. The close collaboration between PHB Die Casting and Machining divisions means that our engineers excel at finding the most accurate and economic CNC solution to finishing your parts. They design and utilize advanced hydraulic/pneumatic work holding fixtures that are specific to each part to improve setup times while also reducing deviations that can occur with manual fixturing. Our engineers rigorously time study each part to improve the machining process wherever possible. In addition to our CNC capabilities, our machining division can offer in-house assembly, advanced leak testing, and impregnation.

Superior Quality Driven by an IATF Certififed Quality Management System

At PHB we make the quality of your parts our highest priority. Every die cast design and manufacturing process we perform for OEMs is held to strict standards, meeting and exceeding the requirements of the ISO 9001:2015 and IATF 16949:2016 quality management systems. Our quality engineers lead the charge in applying Core Tools methods to each job we undertake. PHB quality engineers are involved in every process starting from the quoting stage until the parts are out the door. We use our extensive knowledge to provide parts that meet your highest standards every time.

With the ability to serve the die casting needs of industries ranging from Defense to Automotive, our capabilities are vast, and our manufacturing methods are well tested. If your OEM requires die casting work to be completed from design to production, contact PHB for an introductory conversation and a quote.