High-Quality Die Casting | Fabricated & Machined Products

An IATF 16949 Certified Manufacturer & Supplier

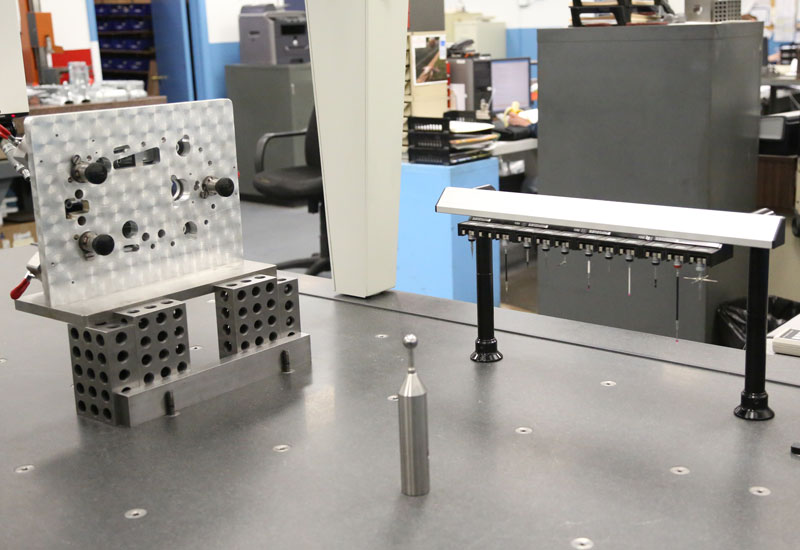

PHB Quality Systems place emphasis on customer satisfaction and the foundation for providing exceptional products that meet specifications and exceed customer expectations. As an IATF 16949 certified manufacturer and supplier, PHB continually aligns our manufacturing quality and organization at the highest levels.

PHB quality system capabilities

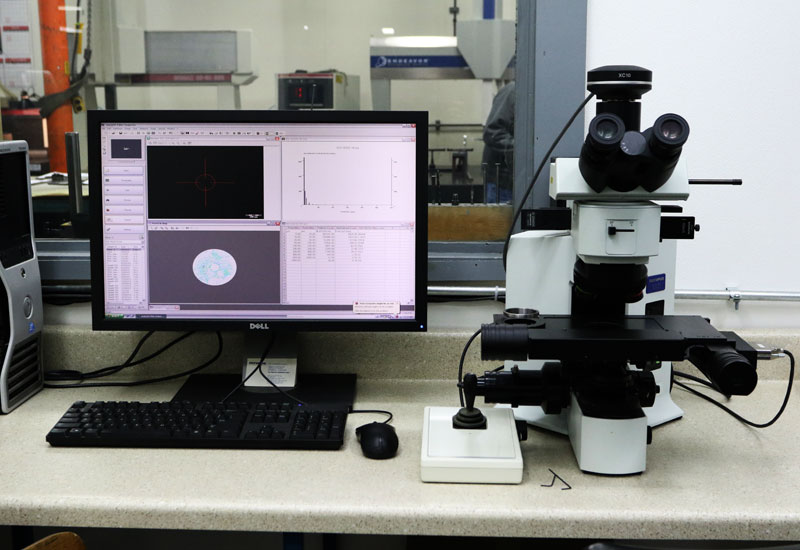

cognex vision system

PHB utilizes a state-of-the-art vision system for verification and optimization of certain common vision tasks, such as checking for the presence or absence of parts and features, inspecting and identifying parts, and detecting defects. PHB has manufactured die-cast parts that can function only if every intricate component has been included through the casting process. PHB can promise the highest level of quality and part performance for industries such as the pharmaceutical, automotive, healthcare, aerospace, and consumer products manufacturing.

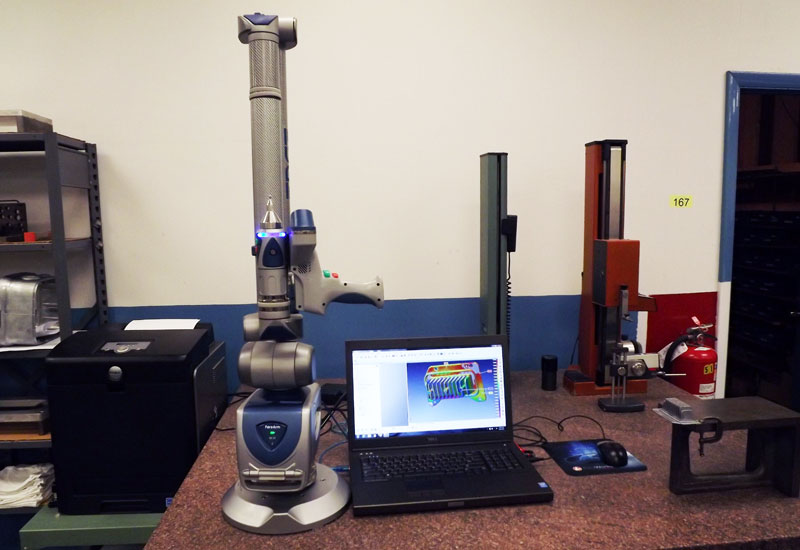

The FARO Edge ScanArm®

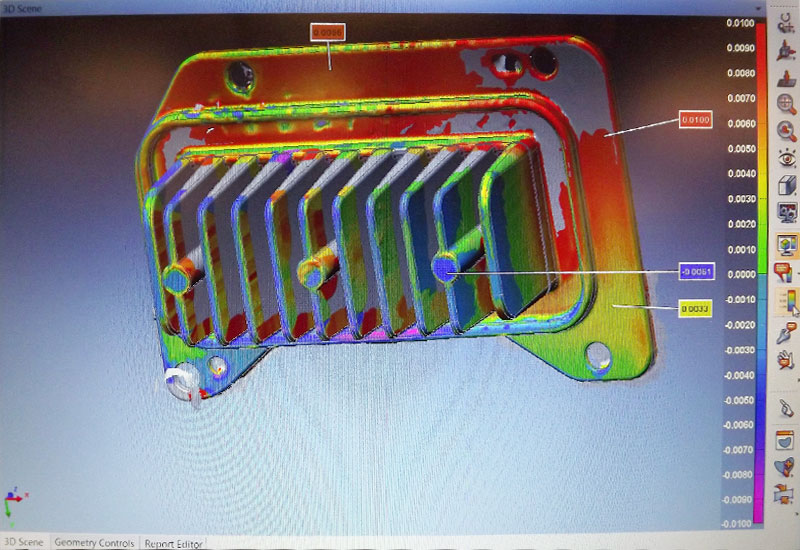

In order to create the highest quality castings and tooling, PHB has acquired a new, non-contact portable laser line scanner. The laser/scanner is used for product development, inspection, and quality control, and offers capabilities such as point cloud comparison with CAD, rapid prototyping, reverse engineering, and 3D modeling. Some of the FARO Edge ScanArm® capabilities are:

- Non-contact inspection of parts, castings and tooling

- Direct to CAD comparisons

- Assist in reverse engineering

- Compatible with Polyworks Inspection software