Why Choose PHB for Close Tolerance CNC Machining?

- Our large facility and staff allows for high volume production and quick turnaround.

- Our testing and quality assurance processes ensure the highest quality products.

- We provide cost-effective solutions to short run production.

- We are an ITAR Compliant Contract Machining Manufacturer

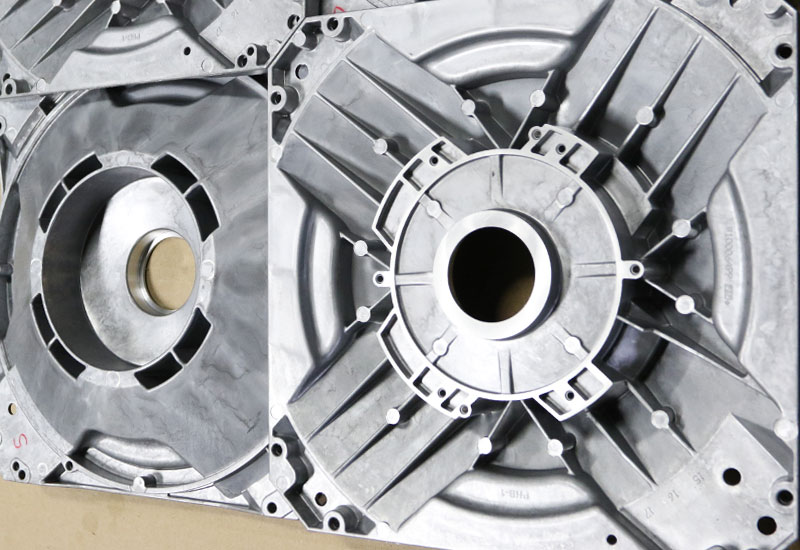

Precision Aluminum & Zinc Cast Machining

PHB Machining offers close tolerance CNC machining capability in turning, milling, drilling, boring and tapping. We also offer assembly and impregnation using Imprex 95-1000A resin, verified through our leak test capability.

We have ten (10) CNC lathes, twenty-seven (27) CNC Horizontal machine centers and twelve (12) Vertical machine centers. These machine centers have spindle speeds up to 18000 rpm and feature high pressure coolant and 4th axis capabilities. Our machines have the capability to manufacture parts up to 36″ in diameter.

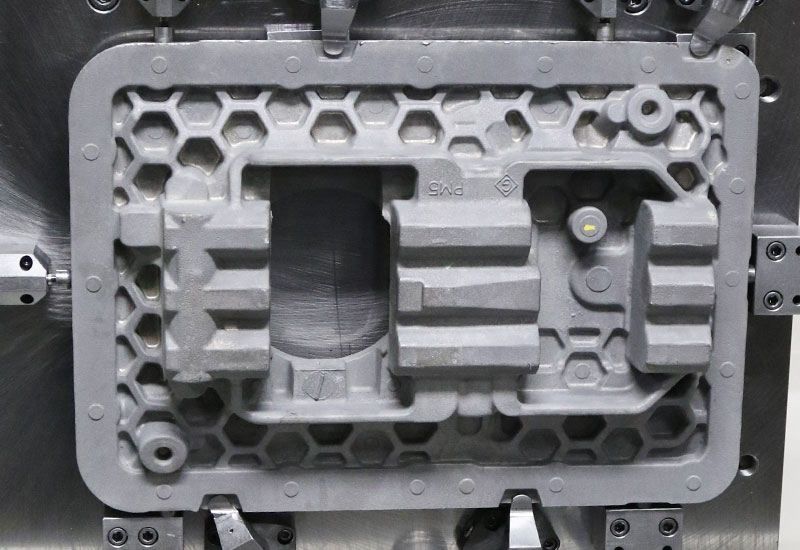

We also have a twenty-eight (28) station Palletech System which allows for quick changeovers and competitive pricing on small volume work.

Although we primarily machine die castings, we also purchase and machine sand castings, cast iron, steel forgings, ductile iron, bar stock, and plastic.

Our assembly department has expanded into brazing, leak testing, and helicoil insertion. We also purchase components and do manual assembly when required. This allows the parts to be shipped to the customers ready for use.

Our state of the art Quality Assurance lab ensures that the product being shipped meets every customer’s standards for low or high volume CNC machining production. We have four (4) coordinate measuring machines which can handle in-process checks to first piece layouts, PPAPs and Quarterly statistics. We also offer Millipore testing that can measure the cleanliness of the parts and make sure that our process meets customer standards.

Aluminum Casting Impregnation

PHB offers complete impregnation capabilities in house for those customers and applications requiring this value added service.

Porosity (shrinkage or gas) can occur naturally in the manufacture of aluminum and zinc die castings. Factors regarding part geometry, tool design and the manufacturing process are all important considerations in reducing porosity. Depending upon the part application, porosity may cause product failures based upon the component’s inability to retain gas or fluids under pressure.

Impregnation is a fast and effective process for reducing the inherent problems associated with porosity sometimes found in die castings. Impregnation is an integral part of the manufacturing process that uses a vacuum chamber. First an impregnation resin is drawn through the casting filling the voids created by shrinkage and/or gas porosity. Next, the resin cures to solid filling the void and eliminates the leak path. Properly processed castings are clean and will have no change in appearance or dimensions. Castings can be impregnated as cast or finish machined.

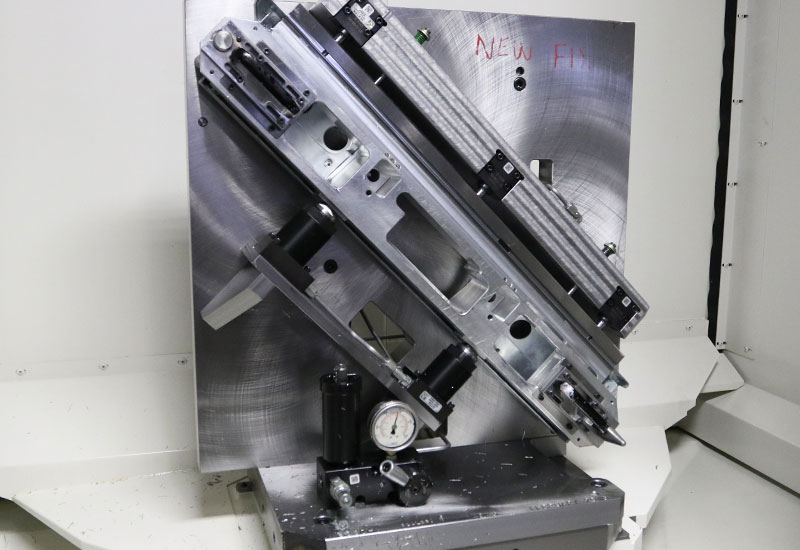

Leak Testing

PHB offers complete leak testing capabilities in house for those customers and applications requiring this value added service.

PHB performs leak testing on a wide variety of products with a large range of sizes and materials.

Our capabilities currently include:

- Water Submersion

- Pressure Decay

- Mass Flow

- Vacuum Decay methods

We utilize test equipment manufactured by Cincinnati Test Systems, and Testra/Unson. Fixturing is designed and manufactured at PHB. Currently we have 20 dedicated test centers and 2 universal systems and are capable of multi stage testing.

Millipore Part Cleanliness Testing

PHB has an in-house Millipore Lab to monitor part cleanliness. This fully equipped lab utilizes a positive flow ventilation hood and Millipore cleaning, collecting, and inspection apparatus and supplies. The latest type of environmentally/operator friendly solvent is used in the testing process. Customer requirements are validated on an audit basis to ensure compliance.

PHB Machining also has a diversified supplier base that allows us to offer other services such as:

- Plating

- Painting

- Mag particle inspection

- Heat treating