Aluminum & Zinc Alloy Specification Conversion Chart for International Die Cast Manufacturing

U.S. Die Cast Manufacturers Competing with Foreign Suppliers

The pros and cons of globalization continues to be a topic of debate for many U.S. manufacturers-now perhaps more than ever with the ongoing tariff and trade wars. When pricing die casted components overseas, many managers often fail to see the hidden costs of doing business abroad. On top of that, quoting specific projects quickly becomes complicated when trying to figure out how the foreign metal specification translates to the alloys poured domestically. The chart below is an easy way to compare and contrast the different specifications of aluminum and zinc alloys between the U.S. and other countries such as China, Japan, France, Italy, Germany, and the United Kingdom.

International Aluminum Alloy Specification Conversion Chart

| USA AA/ASTM | USA SAE | CHINA | UK | Japan JIS H 5302 | ISO | EN AC- | France | Germany | UNS | ASTM B85 | Former SAE J452 | DIN 1725 | Italy UNI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A360 | 309 | YL104 YZA1Si10Mg | LM 9 | ADC3 | Al-Si10Mg | 43400 | A-S10G | G-AlSi10Mg -233 | A13600 | SG100A | 309 | 233 | 3049 |

| 383 | 383 | YL113 | LM 2 | ADC12 | Al-Si10Cu2Fe | 46100 | A-S9U3-Y4 | - | A03830 | SC102A | 383 | 226A | 5076 |

| A380 | 306 | YL112 YZA1Si9Cu4 | LM 24 | ADC10 | Al-Si8Cu3Fe | 46500 | A-S9U3A-Y4 | G-AlSi8Cu3 -226 | A13800 | SC84A | 306 | 226A | 5075 3601 |

| 413 | - | YL108 YZA1Si12Cu2 | LM 6 | ADC1 | Al-Si12 Al-Si12Fe | 47100 | AS 13 | G-AlSi12 -230 | A04130 | S12B | - | - | 4514 |

| A413 | 305 | YL102 YZA1Sil2 | LM 20 | ADC1 | Al-Si12Cu Al-Si12CuFe | 44300 | A-S12-Y4 | G-Alsi12(Cu) -231 | A14130 | S12A | 305 | 231D | 5079 |

Click here for information on a304 K-Alloy

Zinc Alloys

| Commercial | UNS | ASTM B86 | Former SAE J469 | Federal QQ-Z-363a | DIN | JIS | UK BS 1004 | China |

|---|---|---|---|---|---|---|---|---|

| Zamak 3 | Z33520 | AG40A | 903 | AG40A | 1743 | ZDC-2 | Alloy A | ZX01 |

| Zamak 5 | Z355310 | AC41A | 925 | AC41A | 1743 | ZDC-1 | Alloy B | ZX03 |

| Zamak 7 | Z33523 | AG40B | - | AG40B | - | - | - | ZX02 |

| ZA-8 | Z35636 | - | - | - | - | - | - | |

| ZA-12 | Z35631 | - | - | - | - | - | - | - |

| ZA-27 | Z35841 | - | - | - | - | - | - | - |

Disclaimer: This chart is just for reference. The final alloy selection will be based on the customer’s actual alloy chemical composition requirements.

The True Costs of Doing Business with Overseas Die Casting Suppliers

Before the talk of tariffs even became a hot political topic, there were already several areas where hidden costs affected the price of doing business overseas. Perhaps one of the biggest considerations when dealing with a foreign supplier is whether or not an inadvertent direct competitor is created by the order. If the offshore firm anticipates ample demand for a particular component in the domestic market, they may attempt to copy the product and market it to U.S. manufacturers directly. While this can also be a risk with a domestic company, a foreign competitor almost always possesses unfair cost advantages. On top of that, potential legal costs tied to intellectual property laws may cause long-term manufacturing disruptions. Choosing to offshore can risk not only the market share of a particular component but also the loss of that technology as well.

Additional Added Costs of Offshore Sourcing for Die Castings

Up-front costs are fairly easy to estimate for offshore sourcing of die cast tooling. However, there are often buried costs associated with foreign suppliers that usually are not accounted for in a project’s budget. Below is a short list of items for any purchasing manager to consider before putting any formal deal in writing:

- Travel & Lodging Expenses

- Longer Lead times

- Quality Control

- Inventory Considerations

Travel & Lodging Expenses

Communication is understandably the most important factor for creating a reliable component to proper specifications. The more complicated the part, the more traveling required to inspect and ensure components are delivered properly the first time before costly shipping expenses incur.

Longer Lead Times

Because of the distance, longer lead times are needed for delivery. While the time may be negligible, once the shipment process starts, it is almost impossible to tap into the transportation process midstream. This long pipeline makes it difficult to react quickly if engineering changes are required, adding time and money to any given order.

Quality Control

Most always, dealing with a foreign supplier is cheaper on the front-end, but sometimes manufacturers get what they pay for in terms of quality. Even if the metal used is of proper specifications, trouble with design and workmanship may require extensive welding on die cores and other major tooling repairs upon delivery. Furthermore; language, distance, and cultural barriers make communicating the initial design and/or changes difficult too. If an engineer needs to travel abroad to effectively communicate the order, that can also add time and money to an already frustrating order.

Inventory Considerations

Shipping in quantity obviously makes it less expensive, not to mention foreign companies oftentimes require minimum orders. These considerations make it necessary to build in extra inventory storage costs and also eliminates just-in-time (JIT) strategies too.

These items illustrate the reasons why working with a domestic die caster may be just as efficient, if not more, than foreign suppliers. And though there often appears to be significant savings on pure price, this rarely adds up to real cost savings after taking all aspects of the order into consideration. Furthermore, many manufacturers and suppliers develop long-term relationships with each other where payment terms and other items can often be negotiated in good faith because of the trust that exists between the two companies. This also happens with foreign-owned businesses, but the physical distance and cultural barriers can sometimes be too much to overcome. And now with tariffs looming-and some already implemented-the margins may be thinner than ever when dealing with overseas suppliers.

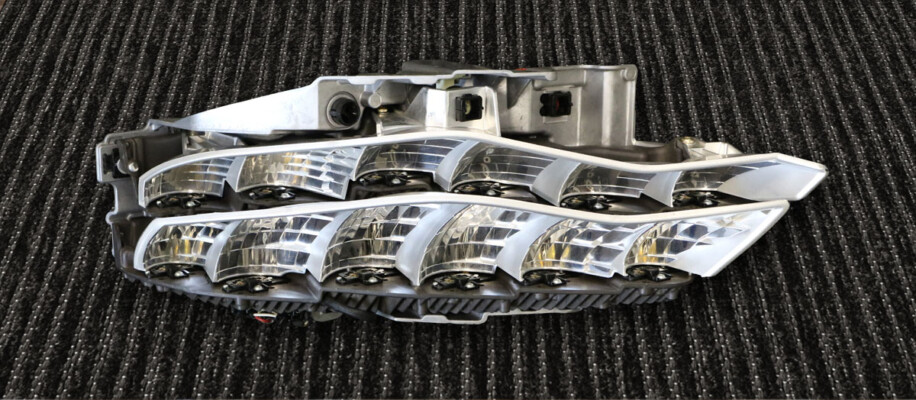

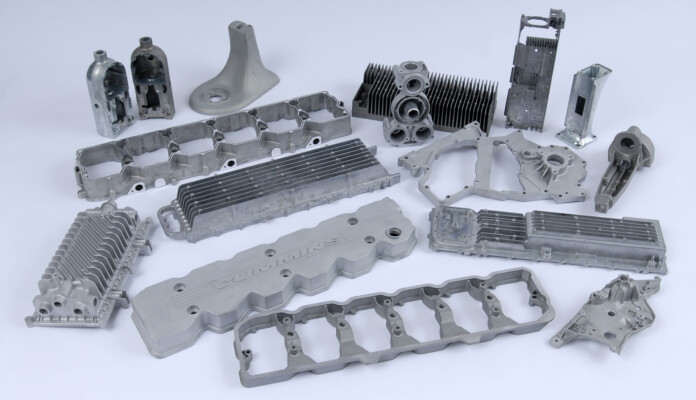

PHB, Inc.– A U.S. Based Zinc & Aluminum Die Cast Manufacturing Company

Located in Fairview, Pennsylvania, PHB is a privately held corporation with roots stemming from die casting since 1906. We became incorporated as PHB in 1984. PHB is recognized across the globe as a fully integrated supplier of quality parts and assemblies. With approximately 500 dedicated employees and over 750,000 square feet of floor space, manufacturing capabilities consist of zinc die casting, aluminum die casting, machining, plastic and rubber molding, tool & die, injection molding, and product assembly.