Why PHB is a Leader Among Die Cast Tooling, Molding, & Repair Companies

- With a fully stocked mold and die component inventory, we provide short lead times on repairs.

- We ensure continuous, high volume, trouble-free tooling and molding using innovative validation.

- Small or large, single cavity or multi-cavity, our mold design capabilities are unmatched

Quality Die Cast Tooling & Mold Manufacturers

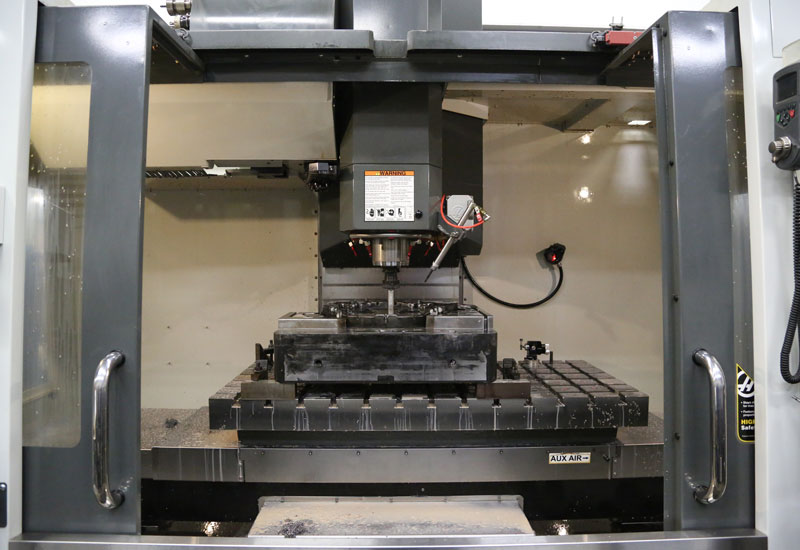

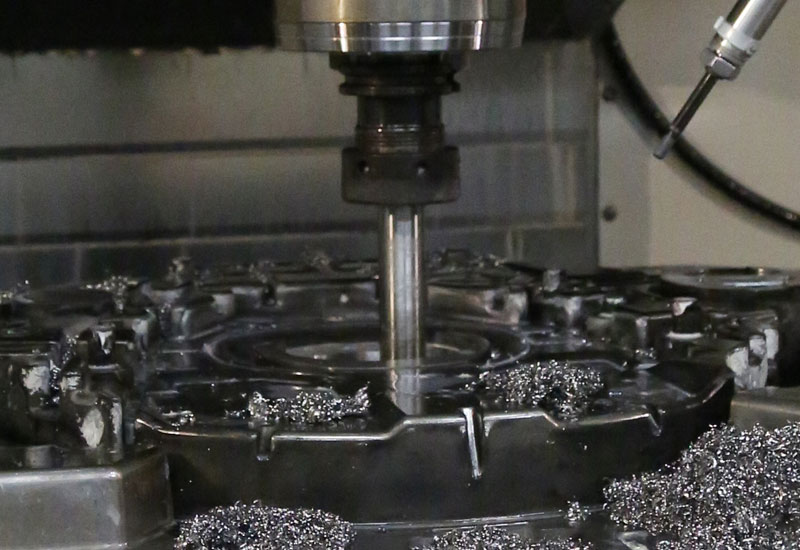

PHB is a tool and die manufacturer committed to the continual upgrading of machinery and equipment to ensure we offer a state-of-the-art die-cast tooling and molding facility. We provide die-cast tooling, die-cast mold revision, and specialized machining for contract manufacturers, including high-pressure injection molds for high-pressure valves, nuclear components, large gearing, and mechanical drives. We also provide turnkey services beyond our mold manufacturing, creating initial designs and prototypes for molds, manufacturing the tooling, designing custom fixturing, and providing the die-cast part production. PHB’s size, lift capacity, and machine capability — comprised of high-speed machining centers, state-of-the-art CNC sinker EDM machines, and extensive engineering expertise — sets us apart from our competitors.

Some of our capabilities include:

- Product design

- Injection tooling and molding design

- Mold and die construction (100 to 2000 ton capacity)

- Die-cast mold revision

- Mold and die repair

- Tool validation

Validation Technology and Mold Flow Analysis

Our die-cast and mold designers utilize the latest technology in engineering and metal flow analysis. As a die-cast mold manufacturer, we understand that our ability to provide your company with superior quality and lower cost hinges on technology and innovation.

Some of our technology includes:

- MAGMAsoft® flow technology

Other engineering software used includes:

- Pro Engineer/CREO

- AutoCAD

Close Tolerance CNC Machining & Value-Added Services

As a premier tool and die manufacturer, PHB provides a number of value-added services for our customers which helps to reduce costs and keep lead times to a minimum. PHB offers close-tolerance CNC machining including turning, milling, drilling, boring, and tapping capabilities. PHB is your one-stop tool and die manufacturer. Our large facility and knowledgeable staff allow for high volume production and quick turnaround. With our testing and quality assurance processes, we ensure the highest quality products with the most cost-effective solutions to your production needs.

Why Reddog?

- Product design.

- Design and manufacturing of new molds and dies.

- Die-cast mold revision and repair

- Mold validation.

MOLD AND DIE-CAST MOLD REVISION AND REPAIR

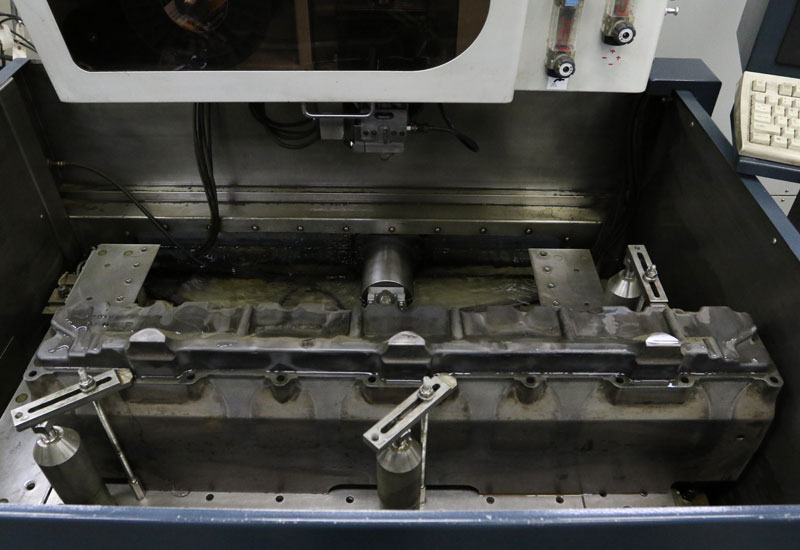

Reddog has developed one of the most extensive mold and die-cast mold revision and repair facilities in North America. Our large-scale machining and crane capabilities allow us to work with molds weighing up to 25 tons while maintaining tight tolerances on intricate features in both injection molds and die-cast dies.

We understand that mold and die validation is essential when repairing or revising a mold, particularly when lead time is critical. By working with a die-cast mold manufacturer with the capabilities of PHB, our mold validation services, including our spotting press and injection molding machines, enable us to return a mold or die to you production-ready.

We pride ourselves on achieving industry-leading customer service and rapid turnaround times, backed by our 24/7 repair and revision operations. When you are facing a line-down situation, Reddog’s team of journeymen mold and die makers are ready to get you back up and running.

Engineering Support: The Backbone of Reddog

Reddog’s team of experienced engineers can support you through product design, injection mold and die-cast die design, and production troubleshooting. We utilize the most advanced technology and engineering software available to validate each step of our process. Our software expertise includes:

- Pro-E CREO

- AutoCAD

Our engineers will work closely with your team to assure a smooth transition from product development through to production. Call or email us today so we can help you with your concept visualization, functional analysis, magma flow analysis, and complete mold or die design.

Die Cast Design

Reddog’s team of die designers utilizes state-of-the-art die-cast manufacturing techniques from expert die-cast mold manufacturer PHB to provide customers with the best aluminum and zinc die-cast solutions available. Our staff of over 45 skilled mold and die makers can provide tooling for parts ranging from 1 oz. to 35 lbs.

- 100 to 2,000-ton capacity

- MagmaSoft simulation

- Prototyping

- Fully integrated systems