Why Choose PHB for Custom Rubber Molding & High Volume Rubber Overmolding?

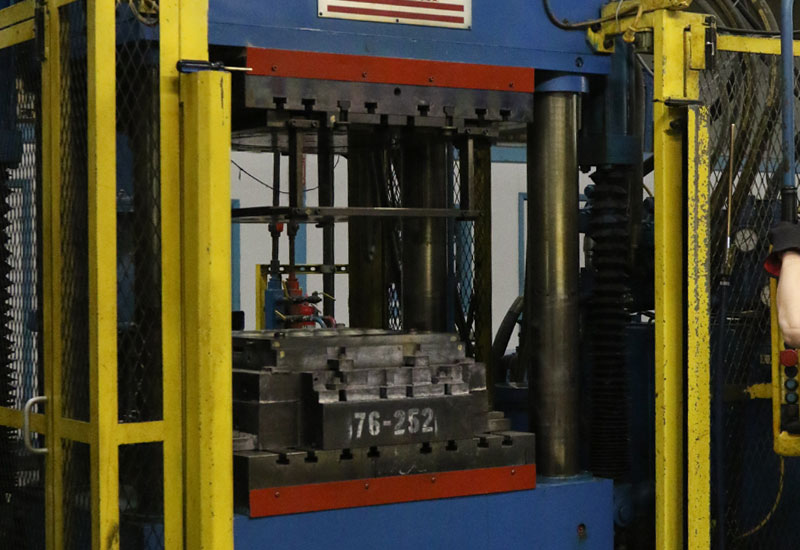

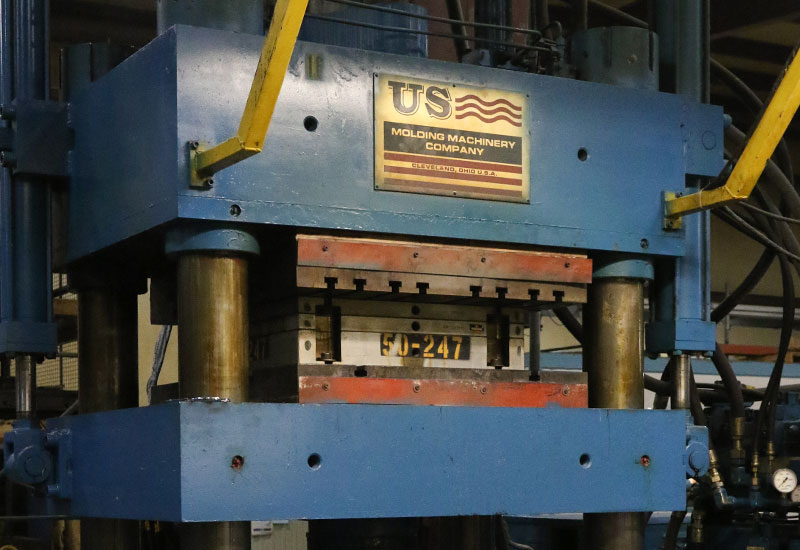

- PHB’s U.S.-based Molding Division produces high volume rubber components.

- Our manufacturing process allows us to provide cost-effective low volume production.

- With a range of rubber types and processes, PHB solves problems in rubber molding and rubber overmolding on a global scale

Rubber molding and rubber overmolding with PHB offers you the ability to design and build tooling while assisting with the design of the product. We also provide prototyping, assembly, product graphics, custom packaging and shipping. Our rubber molders run three shifts of production, including both low volume and high volume jobs. We are able to repair and run older rubber molding tooling as well as provide specific testing and compliance certifications. PHB’s rubber injection molding is ITAR compliant and ISO 9001 Certified. We utilize electronic data transfer and JIT production scheduling to meet customer requirements. Get in touch with us to learn more about our rubber molding services.

What is Rubber Molding?

Rubber molding is a process used for creating industrial rubber parts. This process uses heat and pressure to mold rubber into specific rubber components used in many different industries. This can be done via multiple types of molding processes, including injection molding, transfer molding, and compression molding. PHB specializes in injection molding services, as well as insert molding and overmolding.

Rubber molding has a wide range of uses, and is frequently used to make gaskets, tubing, hoses, and many other industrial parts. Both synthetic and natural rubber can be used, and the decision of which to go with is often based on the specific application of the part.

Types of Rubber Used in Rubber Molding

There are many different types of rubber, both synthetic and natural. Each has its own unique properties which may make it a better choice for a specific application. PHB utilizes the following rubbers for its rubber injection molding:

- Viton: Viton has a strong heat resistance, so it’s an ideal material for applications that will experience high temperatures of up to 400° F.

- Nitrile: Nitrile is ideal for applications where it will be exposed to oil, fuel, and grease.

- Neoprene: Neoprene is a great all-around rubber with many applications, and is particularly useful in outdoor applications due to its strong resistance to ozone, sunlight, oxidation, and water.

- Hycar: Hycar has strong physical properties, including good heat resistance, but its strongest property is its resistance to water and fuels.

- Silicones: Silicone is one of the purest and most durable forms of rubber, which allows for its use in food, medical, and pharmaceutical applications.

- NR:Natural rubber has strong all around physical properties, with good resistance to ozone, sunlight, oils, petroleum, oxidation, and water.

- EPDM: EPDM is commonly used for outdoor applications, most famously for roofing. This is due to its strong resistance to ozone, extreme temperatures, and UV.

- Custom Blends: Depending on the application, creating a custom blend to maximize the necessary properties may be your best option. Get in touch with us to learn more about making a custom blend for your application.

Advantages & Disadvantages of Rubber Molding

Rubber molded products have many advantages. First, this process allows for customization, both in regards to materials used – PHB offers many different types of rubber with different properties – as well as the ability to mold that rubber into the exact shape needed for a part. Rubber itself is also a great material to use for many applications due to its strong physical and chemical properties, including water resistance, durability, and ability to maintain its shape.

There are also many advantages to using injection molding to make rubber parts. This includes short cycle times, which allows for mass production of parts in a short amount of time. Injection molding is also flexible, and overall is an efficient and cost effective process for mass production.

The main disadvantage of using injection molding for rubber is its initial tooling cost. The initial setup and machinery are costly, which is why this process is most cost effective when producing high quantities of rubber parts.

Rubber Molding Capabilities

Injection Molding

PHB offers injection molding for the manufacturing of rubber parts. Our team of consultants and engineers will help provide you with all of the information you need to get the best parts possible for your application. Get in touch with us to learn more about our injection molding services.

Insert Molding

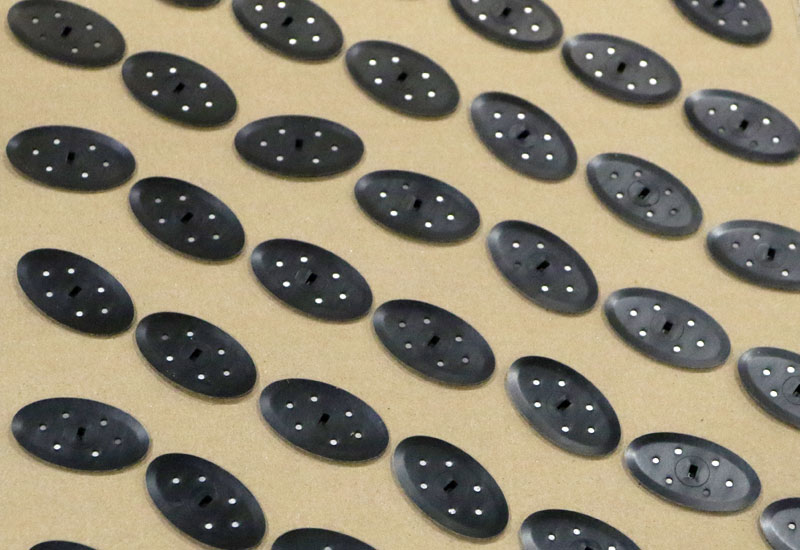

PHB molding produces both plastic and rubber overmolded products. The following is a list of examples to showcase the spectrum of our rubber injection molding capabilities:

- Molding thermo-set rubber over glass filled nylon with a chemlok adhesive that will provide both a mechanical and chemical bond between the two parts.

- Overmolding of brass or steel threaded inserts into thermoplastic parts.

- Post sonic welding threaded inserts.

- Overmolding thermo-set rubber on metal products

Industries Served

Rubber molded parts have many applications across many different industries. PHB proudly serves a wide variety of industries, including:

- Railway

- Appliance

- Automotive

- Electronic

- Military

- Aerospace

- Medical

- Safety Appliances

- Transportation

- Industrial Products

- Home Products

- Railway

- Appliance

- Automotive

- Electronic

- Military

- Aerospace

- Medical

- Safety Appliances

- Transportation

- Industrial Products

- Home Products

CNC Machining & Other Services

PHB provides a number of value-added services for our customers which helps to reduce costs and keep lead times to a minimum. PHB offers close-tolerance CNC machining including turning, milling, drilling, boring, and tapping capabilities. PHB is your one-stop-shop manufacturer for rubber molding and CNC machining. Learn more about our CNC machining capabilities.

Other additive services include:

- Custom trimming of rubber products

- Custom assembly services

- Special labeling of products

- Creating multi-colored, decorative silkscreen labels and logos

- Special packaging

- Cryogenic deflashing of rubber products

- Rubber surface finishing & gluing

Why Go to PHB For Your Custom Rubber Molding Needs?

With over 100 years of manufacturing experience, PHB is your best bet for all of your custom rubber molding needs. We are a global manufacturing leader that takes pride in the quality of our work, including completing projects with the government and military. We are ITAR registered, and ISO and IATF certified. Contact us today to learn more about how we can help provide you with top notch service for all of your molding needs.