Aluminum & Zinc Casting Manufacturer | Precision Machining Supported Die Casting

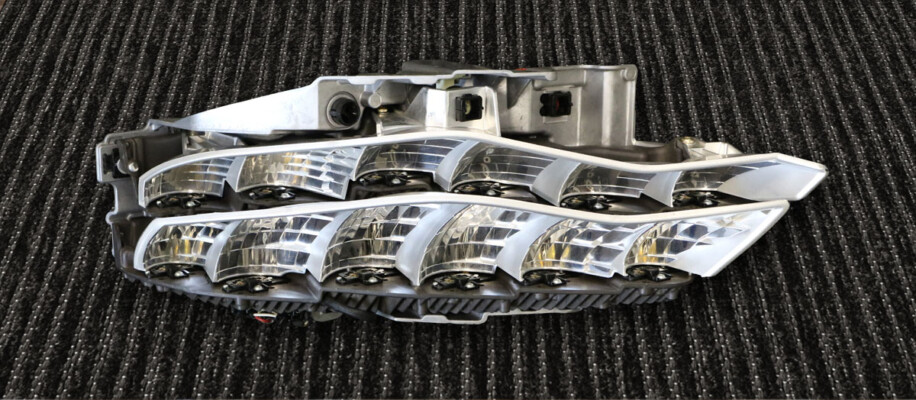

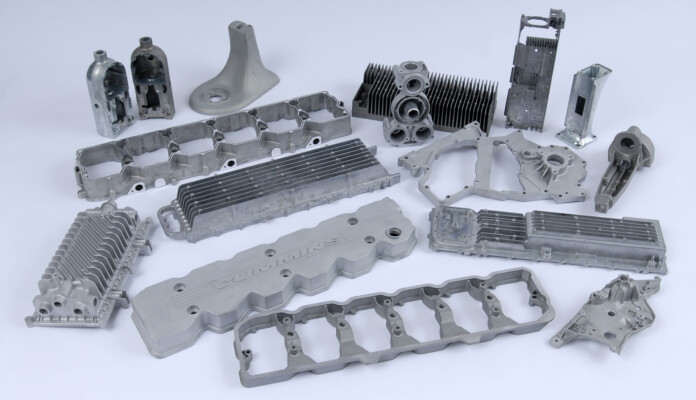

PHB Corp. is a leading casting manufacturer supplying precision machining supported aluminum die casting, zinc die casting, tool and die, injection molding, and CNC machining services. PHB produces castings for some of the largest OEMs in the United States. We produce everything from lighting castings to automotive castings, as well as high-end appliances and products for the U.S. military. PHB’s various press sizes ranging from 100 tons to 2,000 tons allows us to offer single and multi-cavity molds. At PHB, we have the capability to design, prototype, reverse engineer, machine, and manufacture high-quality superior products that are unmatched in the die casting industry.

PHB’s Die Casting Capabilities Include:

- Aluminum Die Casting

- Zinc Die Casting

- Value-Added Services such as:

- Tooling design

- Part reverse engineering

- Mold refurbishing/retooling

- CNC machining

- Finishing and logistics

- Uphold to Specifications (Military & Other Industry Specs)

A High-End Casting Manufacturer & Aluminum Die Casting Company

PHB’s aluminum die casting process produces accurate, defined, smooth, and high-quality metal parts. PHB handles all aspects of aluminum die casting, from mold design and testing to aluminum component manufacturing, finishing, and packaging. Aluminum die casts are great for various automotive components, such as:

- Diesel engine coverings

- Gear casings

- Transmission adaptors

- Valve covers

- Oil coolers

- Intakes

- Rocker lever housings

- Filter brackets

We also regularly produce parts for transportation, communications, home appliance, and medical industries. All aluminum die castings are highly conductive, extremely lightweight, and more cost-effective than alternative casting processes.

PHB Corp. utilizes a high-pressure die casting system to deliver exceptional aluminum die castings. With over 100 years of experience in aluminum die casting, PHB is a world-class leader in manufacturing precision machining supported die castings. Find out more about PHB’s aluminum die-casting manufacturing capabilities today, or contact us for a quote.

A Zinc Aluminum & Zinc Die Casting Manufacturer

PHB works with zinc alloys to manufacture quality, high-pressure die castings. Zinc die castings are great for many applications, including:

- Small kitchen appliances

- Gauging applications

- Thin-walled parts

- Instrumentation

PHB’s highly trained metallurgists ensure that all alloys meet the specifications through continual chemical and physical analysis. In our zinc die casting division, we work with zinc (Zamak 3, 5, and 7) and Zinc-Aluminum (ZA-8, ZA-12, and ZA-27) to provide clients with parts that have high ductility, impact strength, and can be easily plated. Along with handling all aspects of the zinc die casting process, PHB will also manage customer finishing requirements to ensure parts meet specifications in both a timely and cost-effective manner. Our zinc surface finishing includes powder coating, wet paint, chromate, electroless nickel, and more.

PHB’s 58 presses, ranging in size from 100 tons to 2,000 tons, allow Zinc die casting components to be manufactured in both hot and cold chambers (depending on the alloy). Our value-added services extend tool life, reduce cycle times and costs, and provide high quality die castings. Find out more about PHB’s zinc die casting manufacturing capabilities today, or contact us for a quote.

Value-Added Services | PHB is Your Molding and Tooling Partner

With the ability to produce both high-quality aluminum and zinc die castings, PHB is a one-stop-shop for all your casting needs. Additionally, we provide a number of value-added services that can save our customers time and money. Some of our value-added services include:

- Product/tool design & part reverse engineering

- 3D scanning, x-ray, & mechanical testing

- CNC machining/assembly

- Mold and die construction (100 to 2,000-ton press capacity)

- Mold and die repair/retooling

- Quality assurance

- Sub-supplier management & integration

Tooling Design & Reverse Engineering Capabilities for Die Casting

Recognizing technological growth, PHB has committed value-added resources to remain an industry leader in tooling design and reverse engineering. Our resources include electronic process monitoring, computer imaging software (MAGMASOFT), robotics, and state of the art Pro-E and CAD/CAM. Our 3-step reverse engineering process focuses on accuracy, efficiency, and time savings. While other companies often rely on third-party supply chain companies, PHB has the capabilities for rapid identification and mapping of all product characteristics. Our reverse engineering capabilities can take the frustration out of repairing existing tooling and even replace the die inserts without replacing the entire die.

CNC Machining for Die Casting–Mold & Die Construction/Repair/Retooling

PHB’s facility size, lift capacity, and machining capabilities are comprised of high-speed machining centers, CNC sinker EDM machines, and extensive engineering expertise. With approximately 500 dedicated employees and over 750,000 square feet of floor space, manufacturing capabilities consist of:

- Zinc die casting

- Aluminum die casting

- Machining, plastic

- Rubber molding

- Tool & die

- Injection molding

- Product assembly

With the newest CNC machining addition – The Okuma Horizontal Machining Center – PHB’s 50-plus machine inventory is proof that we are committed to consistently improving our customers’ satisfaction.

Quality Assurance | Sub-Supplier Management & Integration Services

PHB Inc. offers cost-effective outsourcing solutions for a wide variety of production and assembly. We take production challenges such as inventory, space, and the cost burdens of assembly out of your plant and into ours, allowing you to focus on growing your business. PHB also takes on the act of managing quality finishing requirement services and ensures end products meet specifications in both a timely and cost-effective manner.

Your Precision Machining Supported Die Casting Manufacturer for Quality End Products

PHB serves manufacturing companies and OEMs that demand the highest level of quality. Our large facility and knowledgeable staff allow for high volume production and quick turnaround. With our testing and quality assurance processes, we take pride in delivering first-rate products with the most cost-effective solutions. Call PHB Corp. today or request a quote to ensure you’re receiving top quality on your next die casting and machining project.

[/wpv-noautop]