Manufacturing K-Alloy / A304 Over A380 & A383 For Aluminum Die Casting

Why The Best Die Casting Manufacturers Are Now Using K-Alloy / A304 Over A380 & A383

K-Alloy/A304 is a patented casting aluminum alloy introduced in 2003 and has been a game-changer for manufacturers as it eliminates the need for processes such as anodizing, chromating, and painting. Eliminating the need for these sometimes expensive procedures not only saves time, but K-Alloy/A304 is engineered to protect components from any kind of environmental damage that may otherwise affect the performance of those components, offering unique engineering solutions over similar diecast aluminum alloys such as A380.

Other than having excellent corrosion resistance properties, K-Alloy/A304 also possesses high elongation properties and has better thermal conductivity for improved cooling over other comparable alloys. For example, K-Alloy/A304 has a 15% better cooling rate over aluminum alloy A380. K-Alloy/A304 does have similar die life to A380 and has the same shrink factors as existing castings while still possessing superior finish quality for high polish applications without needing any special tooling or process parameters.

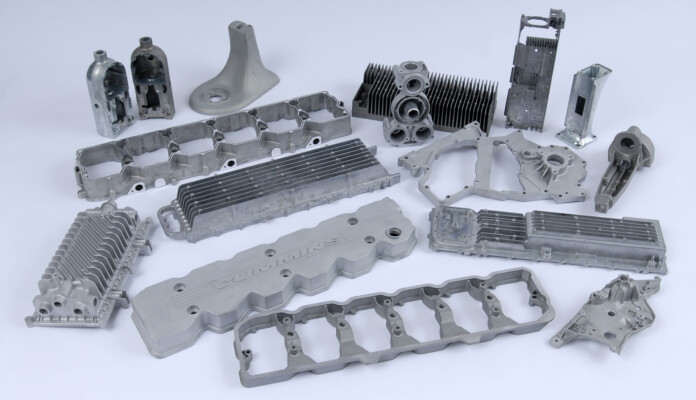

K-Alloy/A304 Castings for Electronic, Automotive, and Commercial Applications

K-Alloy/A304 as a casting alloy can have many different applications. From housing electronic modules to automotive structural parts, to boats and fishing equipment; A304 can be used to guard components from harsh environments and extend the life of those components. It is also used for stadium lighting systems and defense applications such as drones, military radios, and antennas. Please see the list below for some of the industries and applications that K-Alloy/A304 can provide for and be sure to contact us with any further questions that relate to the benefits or applications of K-Alloy/A304.

- Electrical – Housing components such as resistors, capacitors, diodes, relays, integrated circuits, etc. and protecting them from harsh environments.

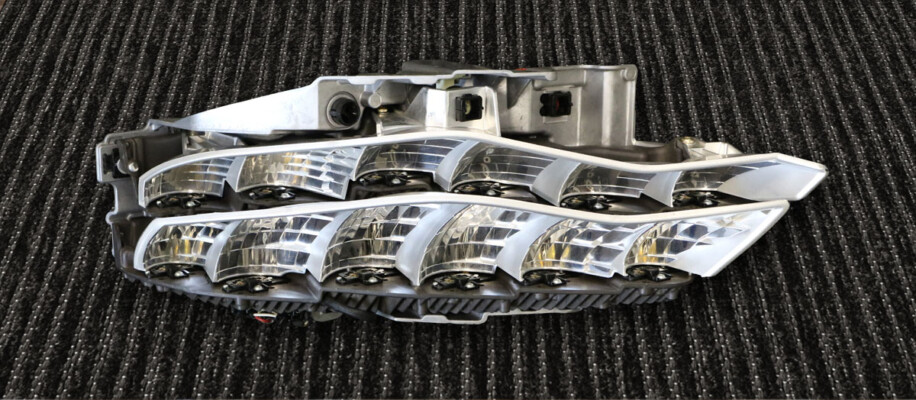

- Lighting – Good for any indoor or outdoor lighting cases such as stadium lighting, street lights, flood lights, boating lights, etc.

- Recreational – Fishing equipment, boating equipment/components, RV’s, etc., anything that comes in contact with harsh conditions very often.

- Automotive – Aluminum alloys are popular for vehicles and harsh under the hood environments with constantly changing temperatures.

- Military – Used in drones, radios, antennas, etc., anything to help vital instruments stand up to corrosion and other damaging elements.

Die Casting with K-Alloy/A304 Over Other Aluminum Alloys

When engineers sit down to create an aluminum part for any application, die casting will most likely be considered as a way to mold the desired part. Aluminum die casting, in particular, is considered a very sustainable and cost-effective way to perform the casting process for many different reasons. Aluminum is a great material for die casting because it provides a combination of being lightweight while also having superior strength compared to other metals. Aluminum alloys, in particular, hold up especially well under high heat conditions–important for many die casting applications. There are many different aluminum casting alloys available for die casting, below is some information on different aluminum alloys available for the casting process.

A380 Aluminum Alloy

A380 is a popular aluminum molding alloy simply because it demonstrates to hold up very well to high heat – making die casting much easier with intricate parts or thin walls. In addition to A380 retaining dimensional stability, it has very high thermal and electrical conductivity. Thermal conductivity may be the biggest difference when comparing it to K-alloy/A304 as A380 is about 15% less conductive than K-alloy/A304. They are both highly resistant to corrosion and hold up well in high heat, but thermal conductivity is important when casting aluminum parts.

A383 and A360 Aluminum Alloys

There are really only two other cousins in the aluminum alloy die casting material family, A383 and A360. A383’s specialty is the ability to create very intricate and complicated molds requiring specific die-filling characteristics. A383 isn’t as strong as K-Alloy A380 but still holds up well enough to complete complex aluminum die casting. A360’s biggest pro is being the strongest and least-corrosive of the family. The con is A360 can be very difficult to cast, and is therefore avoided by many aluminum die casters. Again, though while K-Alloy A304 may be somewhat weaker, comparatively it can be the better choice depending on the aluminum casting requirements and needs, but A304 generally encompasses the best of both worlds being easier to work with while staying very sturdy.

Using Zinc-Aluminum Alloys for Die Casting

Zinc-Aluminum Alloys were first designed for gravity casting, but have since been adapted for die casting as this family of alloys also exhibits the good strength and durability needed when casting. Usually, zinc aluminum alloys are used for specific permanent mold applications such as bearings or thin wall decorations as they contain a higher aluminum content than standard zinc alloys. Common zinc aluminum alloys include ZA8, ZA12, and ZA27. The number after the ZA designation represents the percentage of aluminum in the alloy. ZA8 for example, one of the more popular zinc-aluminum alloys, contains approximately 8.4% aluminum. ZA8 has better tensile strength than other commonly cast alloys, and because of that, is the only zinc-aluminum alloy that can be cast in a hot-chamber die cast machine. However, depending on the application, K-alloy/A304 can be considered a better all-around casting alloy and therefore a better alternative depending on the intricacy of the part being produced. If the walls don’t require being too thin, A304 will still be a better overall alloy, but every die cast part has its unique requirements.

Choosing the Best Aluminum Alloy & Die Casting Manufacturer for the Job

PHB Inc. is based near Erie, Pennsylvania in Fairview and is a full-service supplier of aluminum die casting, zinc die casting, CNC die casting machining, and many other industrial services. PHB is able to serve manufacturing companies and OEMs demanding high-quality castings. As an ITAR registered ISO certified die casting company, PHB Inc. is able to compete for government and military work. Applications of our castings range from lighting to automotive to appliance industries and everything in-between.

Because there are so many variations of alloys, it can sometimes be confusing when choosing the right alloy for the right part when die casting. Depending on specifications and applications the end-product is being designed for can all vary the alloy needed for die casting. Use the specification chart below for further information. For more information about selecting alloys, call or contact PHB Inc. today to talk to an expert about all the different aluminum alloys and zinc aluminum alloys available for your next application.

K-Alloy / A304 Property Comparison Chart

| Alloys | |||||

|---|---|---|---|---|---|

| K-Alloy/A304 (As Cast) |

360 | 380 | 383 | 413 | |

| Tensile Strength (PSI) | 43,000 | 46,000 | 47,000 | 49,000 | 42,000 |

| Yield Strength (PSI) | 25,000 | 25,000 | 23,000 | 23,000 | 19,000 |

| Elongation | 5.00% | 3.5% | 3.5% | 3.5% | 3.5% |

| Thermal Conductivity (W/m.K @ 77°F) |

120 | 113 | 96 | 96 | 121 |

| Density (gms cm-3) | 2.63 | 2.63 | 2.71 | 2.74 | 2.66 |

| Corrosion Resistance (10 = best, 1 = worst) |

10 | 6 | 3 | 3 | 6 |

| Die Life | 100% of A380 | 100% of A380 | 100% of A380 | 100% of A380 | 100% of A380 |

choose phb for your aluminum die casting manufacturing needs today

[/wpv-noautop]