X-Ray Imaging of Cast Parts to Identify Subsurface Defects

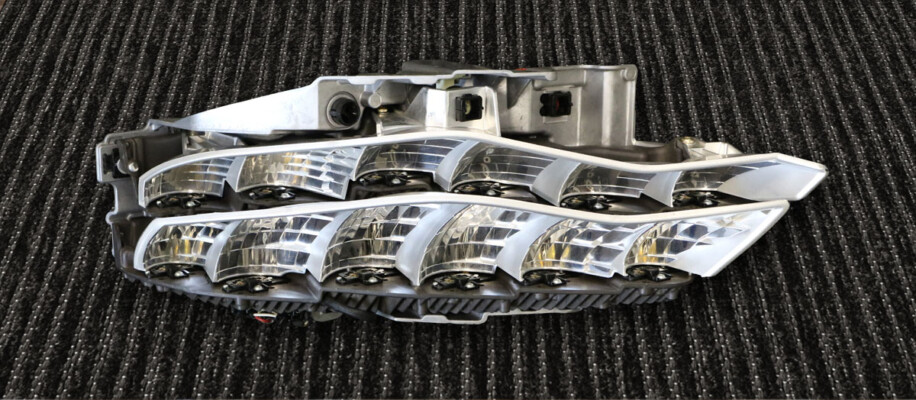

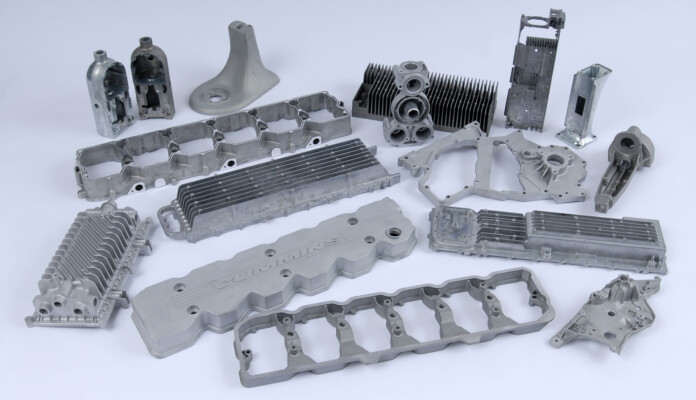

At each stage of the casting process, foundries take careful steps to ensure that the pieces cast are sound. From pattern-making to finishing, metallurgists diligently ensure that surface finish, mechanical properties, and castings’ dimensions are accurate and to standard. However, even when castings are produced with extreme care, factors like slight temperature fluctuation and imperfections in casting materials can wreak havoc in finished products. Thorough inspections are crucial to control for these unforeseen imperfections in a product.

For foolproof inspection, radiographic imaging is the gold standard for identifying subsurface defects in castings. Diagnostic foundry X-rays serve manufacturers the same way they do emergency room staff: invisible problems are revealed, and immediate action is taken to ensure that they are solved. In people, bones are set and illnesses are treated. In cast parts, cracks and bubbles are identified immediately, and the appropriate adjustments are made so that time and money aren’t wasted reproducing imperfectly cast components.

How PHB Performs X-Ray Imaging of Cast Parts

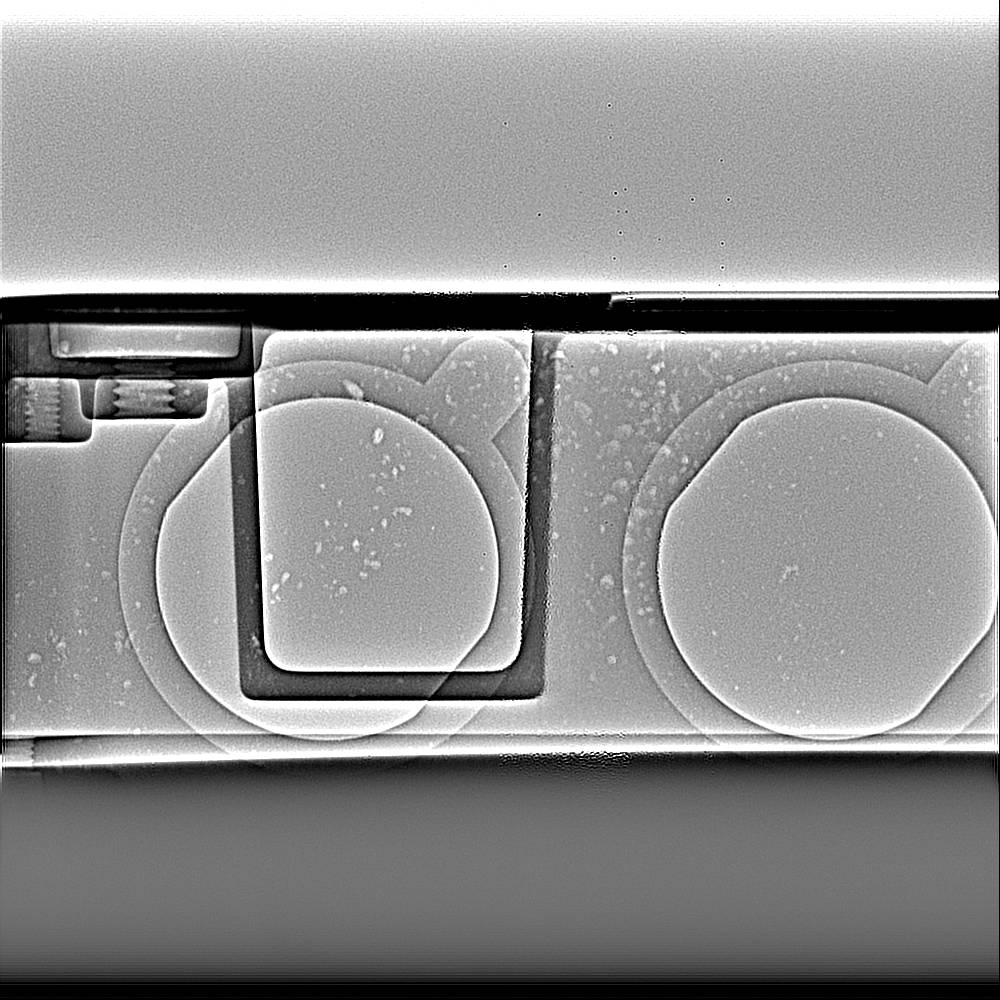

Using sophisticated x-ray technology, cast parts are scanned with radiation in an x-ray tube. The resulting images show the density of the part they have scanned – less dense areas show up light, and more dense areas are dark.

Holes, cracks, bubbles, and inclusions are revealed as lighter areas on the digital image produced by an x-ray machine. When these light areas appear, specially trained process control technicians intervene and inform coworkers of the imperfections that have been revealed. Our process control team can then adjust their temperatures, pressures, and other variables to ensure that the defects are addressed before production carries on, and well before cast items are machined, leak tested, or finished.

X-Ray Inspection of Cast Parts Saves Time and Money

In foundries without PHB’s capability for x-ray inspection of cast parts, a typical production run might look something like this:

- A die is set up to run production, and a small lot of castings is sent to the machining division to be machined while casting continues.

- After a few days of production, an issue emerges in the machine shop: in area “z” of the casting, a void in the cast part has appeared repeatedly. Due to general consistency between castings, it’s reasonable to assume that the same internal defect recurs in every casting.

- All castings that have been made so far are now scrapped, time is lost, and adjustments are made before the whole lot is re-cast and re-machined.

The same process in PHB’s x-ray and CT-capable foundry:

- The die is set up for its run, and an initial sample is taken straight to the x-ray machine to check for internal defects.

- Internal defects are identified immediately; furthermore, other defects like potential leak paths and failure points that wouldn’t be revealed during machining (those in addition to area “z”!) also appear on the x-ray. These imperfections are noted and addressed, and solutions are drawn up in real-time, leaving no time or materials wasted.

PHB’s X-Ray Equipment and Capabilities

With the power of the YXLON MU2000-D, PHB’s technicians can swiftly identify and combat hidden quality issues in castings, including:

- Gas Porosity

This involves the formation of voids in the casting that are caused by trapped air or other gases. These voids appear as small light circles on the x-ray image.

- Shrinkage Porosity

Shrinkage porosity is formed during the cooling and solidification process of casting. You would see this defect as angular edges, mottled areas, light streaks, and branch-like fractures.

- Inclusions

These appear as irregularly shaped holes inside the casting due to unwanted particles of sand, material, dross, or deoxidation in the metal casting.

- Other imperfections include detectable dross, cold shut, segregation, diffraction, and diffused chaplets.

Exceptional Quality in Casting at PHB

X-ray imaging of cast parts is a popular technique to identify subsurface defects in castings. PHB is proud to offer this nondestructive inspection method for detecting internal defects in castings. We are able to inspect our products with confidence, knowing that their structure and mechanical properties are sound. Our customers can rest assured that their cast components are free from any issues that could cause problems after assembly. Contact us today to explore how our exceptional casting and quality control measures can benefit your future projects.

[/wpv-noautop]