Providing OH & MI With IATF 16949 Certified Die Cast Manufacturing for Automotive Parts

IATF 16949 Certified Die Cast Manufacturing for Automotive Parts

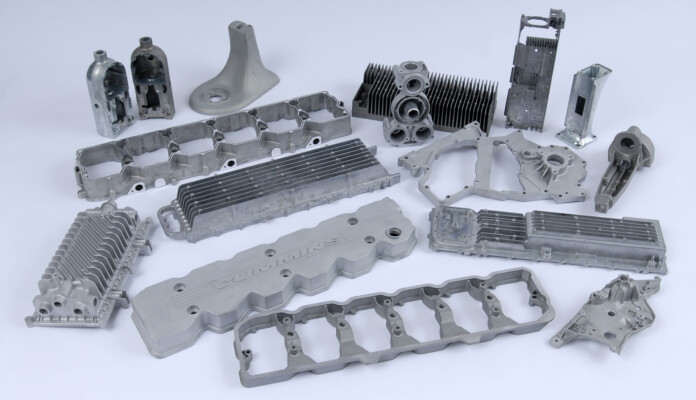

PHB Corporation has extensive experience helping automotive manufacturers in Ohio, Michigan, and throughout the U.S to prototype, design and manufacture aluminum and zinc die cast parts. Our 58 die casting presses allow us to produce castings for automotive use ranging from large to small, high to low volume, and all levels of complexity.

Why Choose PHB as Your IATF Certified Automotive Die Cast Part Manufacturer?

- PHB is conveniently located in Erie, Pennsylvania near both Ohio and Michigan, reducing the cost of shipping and also allowing for onsite visits either to PHB’s 750,000 square foot facility or us to yours.

- PHB can help consolidate your supply chain by offering the complete package of die casting services in addition to engineering support, mold design and troubleshooting, machining, and logistics.

- PHB is an ISO Certified Die Casting Manufacturer and has extensive experience in designing and manufacturing zinc and aluminum parts to automotive quality specifications.

- With presses ranging from large to small, we have the capability to manufacture automobile parts of all sizes, from a valve cover to large housings for trucks.

- We are ITAR certified and can provide part manufacturing for military and aerospace applications.

- Our technology facilitates and streamlines production. Our suite of technology includes AutoCAD, Pro-E, MAGMAsoft®, CAD/CAM and EDI compatibility, and FARO Laser Scanning.

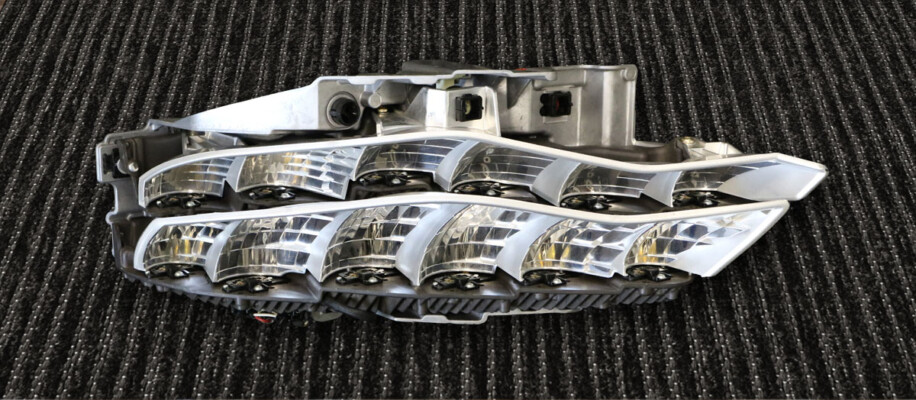

Large Tonnage Die Cast Part Manufacturing

PHB’s die casting operation features 58 presses ranging from 250 to 2000 ton. We accommodate some of the most demanding automotive part runs in terms of volume, part size, and complexity. Because of our engineering and modeling capabilities, we are known by our clients as a company that can reduce part complexity, and make the manufacturing process more efficient. As an example, this die casting case study features a headlight assembly that required 8 separate castings. PHB was able to reduce the cost of tooling and production significantly by designing the part using 4 castings.

Some of Our Die Cast Large Tonnage(1000 ton to 2000 ton press) Automotive Parts Include:

- Adaptor sensor using a 2 cavity mold and 1400 ton press

- Gear housing using a 2 cavity mold and 2000 ton press

- Lube oil filter head using a 1 cavity, two pull core, 1000 ton press

- Filter support using a 2 cavity, 1600, and 2000 ton presses

Our experience in manufacturing automotive parts and our reliability has allowed us to often start by producing a few parts for a customer, then growing to that customer relying on us for nearly every type of aluminum component for the automotive application. A shortlist of parts we’ve manufactured include:

- Diecast aluminum headlight assemblies and LED heat sinks

- Fuel filter heads and supports

- Crankcase covers with P-20 inserts

- Transmission and pump adaptors

- Rocker lever housings

Alloys and Finishes for Your Castings

PHB has the expertise to help you choose the right alloy for the application if needed. We utilize a wide range of alloys to meet specifications of temperature, use, and strength. Some of our commonly used aluminum and zinc-aluminum alloys include AL360, AL380, AL383, and AL413, ZA-8, ZA-12, ZA-27. We also provide casting services using K-Alloy. In addition to a variety of alloys, PHB offers finishing services including powder coating, wet paint, shot bead blasting, EMI/RFI shielding, chrome, and more.

PHB’s Value-Added Services to Automotive Manufacturers

Many of the parts PHB manufactures are developed with significant prototyping, and design input from our engineering team. We enjoy working with automobile manufacturers that rely on our Design for Manufacturing (DFM) expertise. After the design process is complete, we build the tooling and manufacture the casting. We then provide the finish machining, multi-spindle drilling and tapping, deburring, impregnation, leak testing, labeling, and other secondary operations for most of our automotive castings.

Ready to have a conversation about your automotive part?