CNC Machining vs. 3D Printing for Prototyping

Prototypes are an extremely valuable and practical asset to have. They allow you to see, feel, and test a product, as well as ensure that it will fit where it’s supposed to and the way it’s meant to. Of course, most designs require some degree of tweaking; it’s likely you’ll go through a few iterations before getting exactly what you need. But the faster you receive your prototypes, the quicker you can make these tweaks and get to market. We’d like to compare the applications of both CNC machining and 3D printing for prototyping purposes.

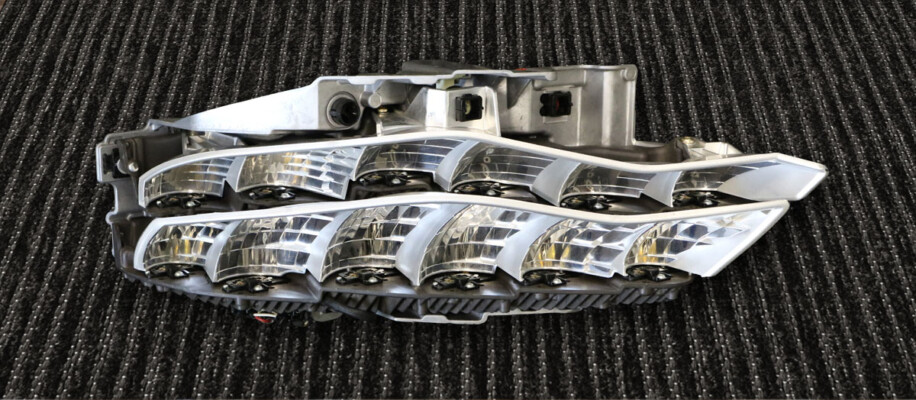

Understanding the 3D Printing Process | 3D Printing for Prototyping in Erie, Pa.

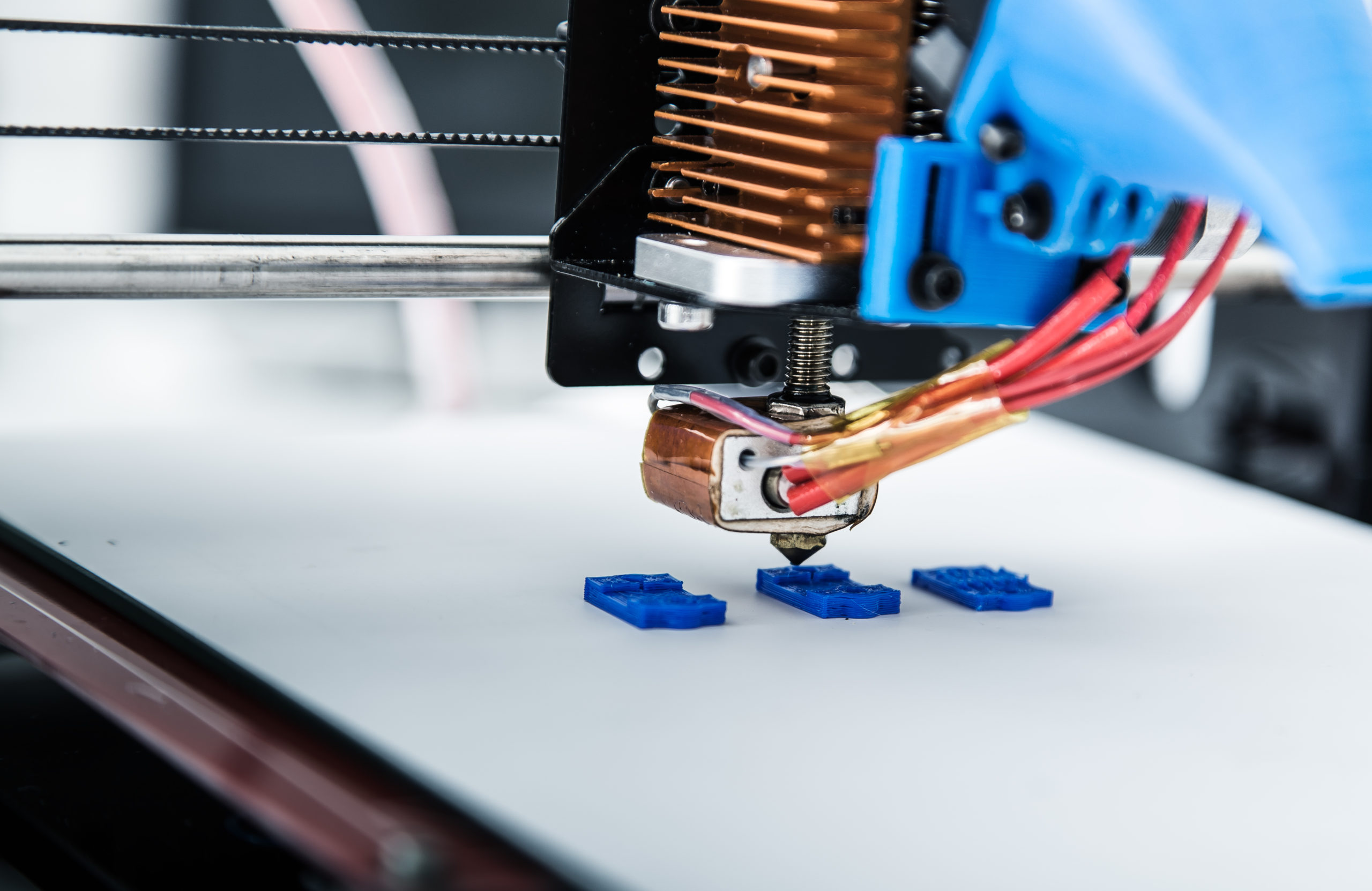

PHB is capable of facilitating 3D printing for both prototyping purposes and the production of durable, end-use products. Our Fused Deposition Modeling (FDM) printer utilizes thermoplastic filament, a high-performance plastic material that is durable when it is heated and solidifies as it cools. We also have a Dual Extrusion printer at our disposal that is capable of printing several different materials (or multiple colors of the same material) in a single print. In fact, PHB is capable of printing nearly any FDM printer material available, including ABS, polycarbonate, NylonX, carbon fiber reinforced, NylonK Kevlar reinforced, and NylonG glass reinforced. In terms of size, we can print parts in a single piece up to roughly one cubic foot (13” x 9.4” x 11.8”), and for larger parts, we simply print in several sections and assemble them for our customers after the fact.

Perhaps the most practical benefit of 3D printing is the way it can reduce the cost of fixturing and tooling. It also saves our team time when it comes to having to program additional machining equipment, as CAD files can be imported directly into a 3D printer. Contact us today to learn more about PHB’s 3D printing and prototyping capabilities.

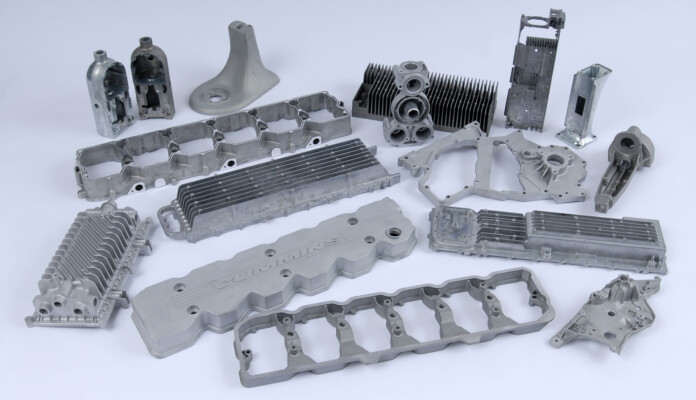

CNC Machining For Prototyping Your Parts & Components

With the unique and strategic CNC machining techniques and tools we use, PHB has the capability to go from a CAD model to a machined part in a matter of hours. One of the biggest benefits of utilizing CNC machining for prototyping means being able to have a prototype machined with the exact material you want your part made from. Additionally, it means this prototype part will be suitable for functional testing. CNC machining also offers final part precision, meaning it is made to print and can be fit to mating parts. For many customers, CNC machining may be the quickest way to get the prototype they need in their hands.

Prototyping with 3D Printing & CNC Machining in Erie

For these reasons, more often than not, CNC machining is going to be the faster and more efficient method of creating prototypes, especially when compared to 3D printing. However, 3D printing is appropriate in many scenarios, such as when you are looking to save costs, include features that machining can’t produce, or simply want a low-fidelity part to hold in your hand. Regardless, if you’re looking for prototype parts made quickly, bring your design to us and we can walk you through all of your options and the benefits that come alongside them. Contact PHB to get started on your next prototyping project today.

[/wpv-noautop]