How to Choose the Right Aluminum Parts Manufacturer

How to Choose the Right Aluminum Parts Manufacturer

An aluminum parts manufacturer needs to be especially reliable if you need solutions for high end applications, and PHB is committed to acting as your partner throughout the entire manufacturing process. Our comprehensive capabilities focus on part design, material selection, high volume manufacturing, and quality control using tools like APQP, FMEA, PPAP, MSA, and SPC. We maintain our commitment to quality by being IATF 16949 certified, going beyond the requirements set forth in ISO 9001:2015.

Take a closer look at how to choose an aluminum parts manufacturer, and discover how PHB works to exceed your expectations across industries such as appliances, telecommunications, electronics, automotive, medical, transportation, aerospace, defense, and more.

Easy Communication

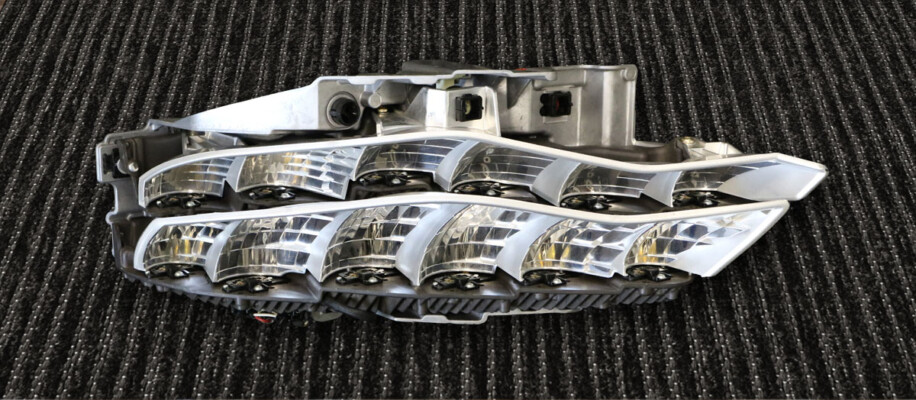

Communicating with your aluminum parts manufacturer should be the easiest part of the entire process. At PHB, our friendly team of experts can help you with every aspect of aluminum die casting, and we are always responsive whether you contact us by phone or email. Explore this case study in which we communicated with a global leader in automotive lighting to create a solution for their need of a two-casting headlight assembly with room for the necessary heat sinks.

Advanced Technology

Throughout the years, aluminum die casting technology has advanced significantly to improve both quality and efficiency in parts manufacturing. Any manufacturer that you choose should be committed to keeping up with the latest advancements and working to make the process as quick as possible while still optimizing the high quality results that you deserve. PHB’s manufacturing process makes use of several state of the art software programs such as AutoCAD, Pro-E, and MAGMAsoft®. Augmented by computer imaging and robotics, our process is designed from the ground up to incorporate the latest technology to boost both quality and efficiency.

Transparency

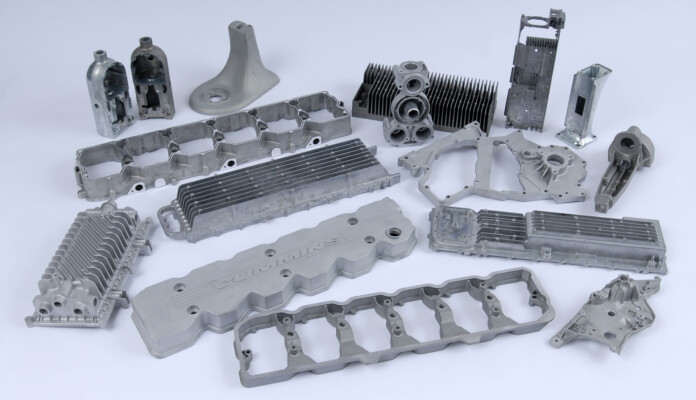

A reliable manufacturer should be transparent about their capacity and processes, and what you can expect from their services. PHB casts a range of aluminum products from prototypes to numerous precision parts. With 22 presses available in our aluminum department ranging from 250 tons to 2000 tons, we can produce components for both low and high-volume applications. Our 500 dedicated employees work with more than 500,000 square feet of floor space to optimize our manufacturing capabilities. We welcome plant tours as well, so you can meet with the engineering team and see the capabilities of our operations.

Convenient Location

If you are operating in the US, then you would benefit from a US-based parts manufacturer. Not only can you expect quality and care being put into the manufacturing process, but PHB’s services stretch from the initial design all the way to delivery of the final product. We are located within two hours of three major airports (Pittsburgh, Cleveland, and Buffalo), which makes on-site visits easy, and can significantly reduce shipping costs compared to more remote manufacturers.

Aluminum Expertise

A reliable aluminum parts manufacturer should understand the intricacies of aluminum to not only grasp how it should be handled during the manufacturing process but additionally how it should be stored and shipped. It is the second-most malleable metal and the sixth most ductile while additionally offering high thermal conductivity and corrosion resistance. Since aluminum itself is not very strong, aluminum manufacturers must have knowledge of alloying aluminum with metals like copper and magnesium. Without proper alloys, aluminum will not be strong enough for certain applications such as airplanes and other vehicles. We utilize many standard die casting alloys to manufacture parts and we can help you choose the best alloy for your application.

Machining and Secondary Operations

Not only is it important to understand the intricacies of die casting aluminum, it is also important to understand the challenges of machining die cast aluminum parts. At PHB Inc we have spent decades fine tuning our machining processes to excel at machining die castings. With our on-site machining division, we are able to reduce lead-time, scrap and headaches by being able to provide real time feedback between die cast and machining. We can cater our die cast process to benefit our machining process and vice versa, saving time and resources.

Industry Reputation

To find a reliable parts manufacturer, you will need to find one that has a positive reputation in the industry. With more than a century of experience, PHB’s reputation extends worldwide, as we are a global leader in aluminum parts manufacturing and prototyping. With our commitment to quality and numerous integrated value-adds like engineering support, stocking program, logistic support, quality control, and intellectual property protection, PHB can be your complete aluminum parts resource.

Contact PHB for Your Aluminum Part Manufacturing Needs

When you are looking for high quality aluminum parts manufacturing, PHB is your global resource for precision and efficiency. Our commitment to utilizing the latest in advanced technology to augment our manufacturing process allows us to remain an industry leader, and we can put that to work for you. Request a quote from our team today by calling us at 814.474.5511 or by filling out our online contact form.