What is High-Pressure Die Casting (HPDC)? | Zinc & Aluminum HPDC

Ever since aluminum parts were first introduced into various industries, manufacturers have been working to determine the best, most efficient processes to produce these parts and ensure that they function properly. One such process is die casting, which can be further divided into subcategories: high-pressure die casting (HPDC) and low-pressure die-casting (LPDC). Choosing the best process for your components largely depends on intricacy, the number of parts involved, and your general budget.

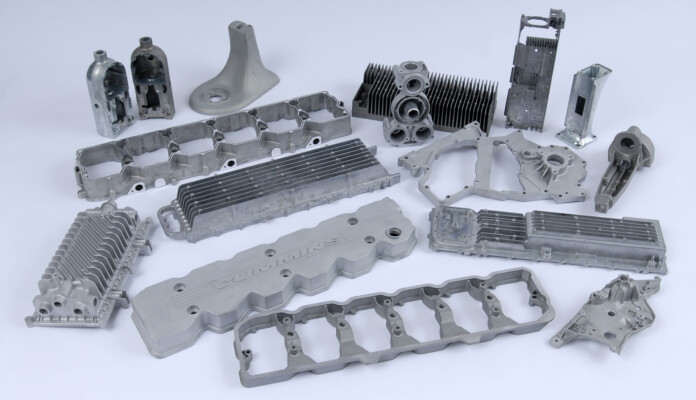

PHB Inc. is not only a full-service provider, but a leader in aluminum and zinc die casting, CNC machining, plastic and rubber molding, tool and die, and injection molding. Through high-quality in-house operations and partnerships, we are capable of providing our customers with superior high-pressure and low-pressure die casting services customized to fit their specific needs and application. Contact PHB today to learn more about our zinc and aluminum HPDC capabilities.

Comparing High-Pressure & Low-Pressure Die Casting Processes

In high-pressure die casting, half of the die is attached to a fixed machine plate while the other half is attached to a movable plate on a horizontally aligned die casting machine. The two halves of the die are held together as pressure is applied during the pour. Cold-chamber casting machines are most commonly used when die-casting aluminum due to its alloys’ relatively high melting point. As molten material is fed into a shot chamber, a piston drives that metal into the die where it will cool and harden. Finally, the die is opened and the casting is released.

Not unlike high-pressure die casting, low-pressure die casting also involves two halves of a die fixed to differing machine plates, but this time, the die casting machine is aligned vertically. A holding furnace for the molten alloy (typically aluminum) can be found underneath the fixed plate, where lower pressure will force the metal up through an intake port and into a die chamber. Once filled, this pressure is maintained as the metal cools and allows for additional material to be applied to counter any volume deficits. Finally, the alloy hardens into a single solid piece.

Benefits & Applications of High-Pressure & Low-Pressure Die Casting

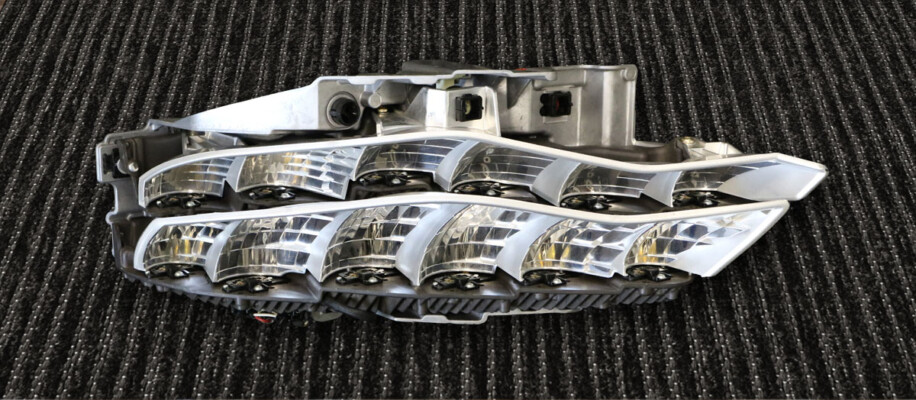

As previously stated, there are many benefits and applications of each die casting process and choosing the best one for your purpose simply depends on the factors surrounding your project. High-pressure die casting is completed in short casting cycles; it is best for thin-walled pieces with smooth surfaces. However, it can also be costlier due to higher operating and die costs. The weight of the die-cast is also limited and can result in lower strength values.

Low-pressure die casting, on the other hand, utilizes a higher percentage of material due to its lack of need for feeders. Low-pressure die casting is commonly used to cast more intricate parts with higher strength values, and to a higher degree of accuracy. The downside to low-pressure die casting is simply the time it takes, typically involving slower casting cycles in addition to requiring a minimal wall thickness of 3mm.

Zinc & Aluminum High Pressure Die Casting in Erie, Pa.

Based on your industry and the application required, PHB can help you determine the best die casting process for your project. We perform aluminum high-pressure die casting and zinc die casting in-house and are capable of facilitating superior low-pressure die casting services as well. While you are here, you may find that you can utilize our high-quality CNC machining plastic and rubber molding, tools and die design, and injection molding services as well. We encourage you to contact us today to discuss your project and how our low-pressure and high-pressure aluminum high-pressure die casting capabilities can benefit you.

[/wpv-noautop]