PHB and BuhlerPrince Promote Solutions to Non-Automotive OEMs

PHB and BuhlerPrince promote thin wall aluminum die casting solutions to non-automotive OEMs

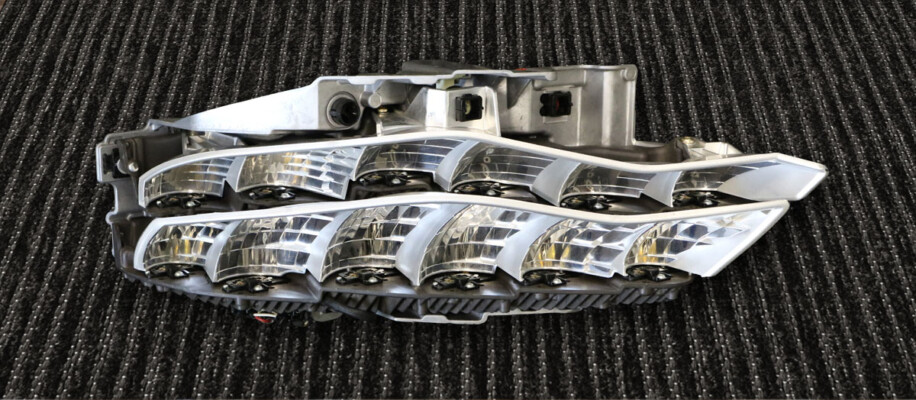

BuhlerPrince, Inc. and PHB, Inc. have made a joint visit to a high-tech and high-end electronics OEM to discuss the topic of thin wall aluminum castings. As many, in both the die casting and automotive industry know, thin wall aluminum parts are the big growth area for castings. This is due to the ever increasing requirement for better fuel economy, lower carbon emissions or both. However, light weighting is becoming very important in many other areas and many other industries outside of automotive and the high-tech electronics industry is now moving in this direction.

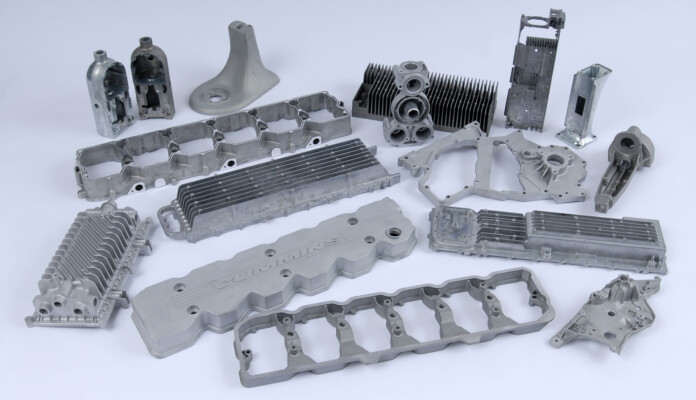

For this joint discussion, BuhlerPrince described all the technical aspects, limitations and potential new breakthroughs which are state-of-the-art today and can be achieved on the Buhler and BuhlerPrince lines of die casting machines. PHB also highlighted their extensive talent and knowledge of how to design these parts, work with simulation software, design the dies and to successfully run these aluminum parts in mass production and test for critical attributes and requirements.

The areas covered during this joint visit included the current minimum wall thicknesses which can be achieved with die casting, the aluminum alloys that are best to use with the different applications, the die design and die materials which are available and all the different process monitoring and process steps which are needed to make thin wall aluminum parts.

PHB and BuhlerPrince have worked together for more than 20 years and this combined presentation showed the strong partnership which exists between the two companies. PHB, Inc., is also investing in new upgrades on their Buhler and BuhlerPrince die casting machines including new Datanet controllers along with other plant investments in laser scanning and vision systems for better quality control and other upstream and downstream process enhancements.

The potential for parts for this one application could be more than 30,000 pieces and there are many other units made by this same OEM, therefore the overall opportunity could be much higher. This OEM currently uses a much higher cost manufacturer process vs. die casting since the application and life testing properties which need to be fulfilled are so rigorous. However, both BuhlerPrince and PHB showed that they have high confidence in achieving these properties even in wall thicknesses which may go down to 25 thousandths of an inch (0.6mm) or possibly lower.

BuhlerPrince and PHB look forward to building upon this already long and well established relationship and to find additional growth areas where thin wall aluminum castings can be used successfully.

About BuhlerPrince, Inc.

BuhlerPrince, Inc., based in Holland, MI USA is an integral part of Buhler Die Casting, Uzwil, Switzerland. As one of (3) manufacturing locations for Buhler worldwide, BuhlerPrince is North America’s leading die casting machine manufacturer. Their products cover machines from 200 up to 4,500 tons of clamping force, a broad range of services for retrofit and/or remanufacturing, local spare parts stock and unsurpassed service and support all catered to the die casting industry. www.buhlerprince.com

About PHB, Inc.

Located in Fairview, Pennsylvania, PHB is a privately held corporation with roots stemming from die casting since 1906. We became incorporated as PHB in 1984. PHB is recognized across the globe as a fully integrated supplier of quality parts and assemblies. With approximately 500 dedicated employees and over 750,000 square feet of floor space, manufacturing capabilities consist of zinc die casting, aluminum die casting, machining, plastic and rubber molding, tool & die, injection molding, and product assembly.

choose phb for your aluminum die casting needs today

[/wpv-noautop]