PHB’s New Okuma Horizontal Machining Center For High Volume Machining

PHB’s New Okuma Horizontal Machining Center

PHB recently installed a new six pallet Okuma Horizontal Machining Center. This machine tool allows us to react quickly to changing customer requirements because of its ability to run production on up to six different parts at the same time. This machine adds to our 50+ CNC machine inventory. The new Okuma HMC is added proof that PHB is committed to the latest and greatest technologies that improve our customer’s satisfaction. PHB’s part lead times have decreased exponentially due to the capabilities the Okuma MA-600HII has for all die casting and machining needs. Some significant features the Okuma MA-600HII has includes:

- A 6 Pallet Changer- Increasing changeover time

- A 110 Tool Changer- Increasing efficiency when switching jobs

- Improved accuracy in all finished products

Feature 1: 6 Pallet Changer

This large CNC machine has six pallets for mounting machining fixtures. These pallets shuttle in and out of the machine as programmed. A huge advantage of this style of machine is having the ability to set up six separate parts at the same time and switch between them instantly. Being able to leave parts set up on the machine saves changeover time which reduces part lead times.

Feature 2: 110 Tool Changer

This machine has a magazine capable of holding up to 110 cutting tools. Typical HMC’s hold 40 to 60 cutting tools. Having the cutting tools already in the machine makes switching jobs much more efficient and reduces part lead time.

Feature 3: Improved Accuracy

The MA-600HII offers a high-performance spindle that improves cycle times and dimensional accuracy. The spindle offers full power from low to high RPM. The high speed, high-performance spindle manages thermal issues associated with high-speed machining.

A Generation of Horizontal Machining Centers

For the greatest combination of high-productivity without compromising accuracy, the Okuma MA-600Hll is an excellent choice. This fourth generation MA machine boasts a series of engineering features that help guarantee the best results for all customers of PHB. These machines are built to perform and this investment is indicative of PHB’s commitment to customer service and satisfaction.

Highlighted Specs of the Okuma Horizontal Machining Center

| MAX MACHINING VOLUME | 39.37" x 35.43" x 39.37" |

| ROTARY PALLET SIZE | 24.80" x 24.80" |

| SPINDLE SPEED | 12,000 RPM |

| SPINDLE POWER | 40 HP |

| RAPID TRAVERSE | 2.362 IPM |

Choosing PHB Corp. & The New Okuma MA-600HII for all Die Casting and Machining Needs

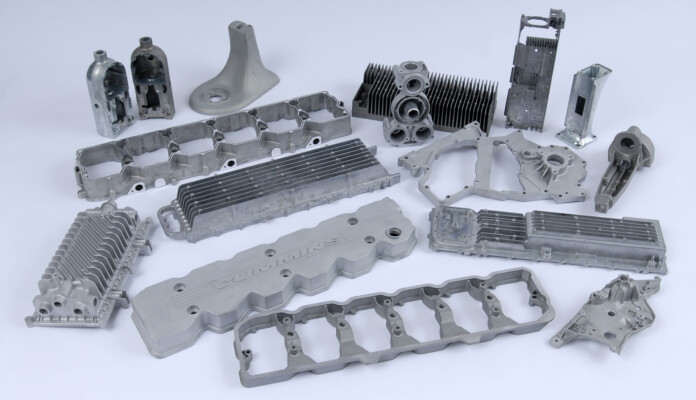

Located in Fairview, Pennsylvania, PHB is a privately held corporation with roots stemming from die casting since 1906. We became incorporated as PHB in 1984. PHB is recognized across the globe as a fully integrated supplier of quality parts and assemblies. With approximately 500 dedicated employees and over 750,000 square feet of floor space, manufacturing capabilities consist of zinc die casting, aluminum die casting, machining, plastic and rubber molding, tool & die, injection molding, and product assembly.