Seamless Supply Chain Reshoring & Replacement Tooling with PHB Inc.

Companies in North America are working to reshore and find more localized supplier partners to create resilient supply chains. According to the above Thomasnet survey, 69 percent of companies across the manufacturing and industrial sectors are likely to bring manufacturing production and sourcing back to North America.

Several factors driving supply chain reshoring include: “The Amazon Effect,” or consumer expectation of rapid delivery, a reduction in the cost of labor relative to companies’ total costs, and increased demand for customized products immediately. Many manufacturers are considering supply chain reshoring as a result of the COVID-19 pandemic and requirements of the U.S.-Mexico-Canada Agreement (USMCA).

There is a bright future in manufacturing and an opportunity for American manufacturers. Bringing projects back onshore bodes well for top U.S. die casting manufacturers, American die casting suppliers, and replacement tooling companies. PHB’s in-house capabilities offer a seamless transition to onshore supply chains as an industry leader in die cast tooling, tool & die manufacturing, plastic molding, rubber molding, machining, and more.

Benefits of Supply Chain Reshoring

The Value of American Made Products

Reshoring your supply chain restores lost jobs and boosts the economy. Additionally, many government contracts and buying agents prefer – or require – products made in the U.S. This also provides opportunities for American workers; the U.S is home to many highly skilled workers. The American worker has built the world’s biggest economy. It makes sense in the context of supply chain reshoring for manufacturers to put that spirit to work for them. Manufacturing and innovation go hand in hand. U.S. workers engaged in manufacturing lead to innovation. Top U.S. die casting manufacturers see employees at every level creatively solving problems and operating more efficiently.

Intellectual Property & Simplified Legal Matters

The U.S. legal system may be complicated, but it is beneficial for a business’s long-term stability. Supply chain reshoring offers greater legal protections for intellectual property, and in the case of IP theft, companies manufacturing in the U.S. have legal recourse and options. Familiarity with the landscape of business laws and protections offered to intellectual property make them easier to navigate. Additionally, some global certifications may require samples for analysis or even disassembly, putting intellectual property at greater risk. Earning global certification in U.S.-based labs is much simpler and safer.

Resources are Widely Available & Affordable

The U.S. offers manufacturers a reliable supply of resources, including electricity and water. Supply chain reshoring means that energy, in the form of oil and natural gas for logistics and transportation, is abundant and therefore cost-competitive.

Simplified Supply Chain Management

Supply chain reshoring creates shorter delivery times and eliminates issues related to customs, tariffs, or potential language barriers and miscommunications. This also leads to streamlined logistics and transportation; shorter transit times associated with supply chain reshoring mean less supply is in transit at any one time. Upon discovering a manufacturing issue, there will be less disruption time. Avoidance of costly and complicated taxes and tariffs is another clear benefit of supply chain reshoring. Uncertainty is causing expensive disruption to global businesses and is likely to be an ongoing issue for years to come.

Greater Quality Control

In its examination of the benefits of supply chain reshoring, GMI Solutions points out that “high-quality components are a cornerstone of a high-quality assembly,” and quality “can be much easier to manage… when it is in the same region as a manufacturer. Closer is better….”

PHB Inc. Helps With Supply Chain Reshoring

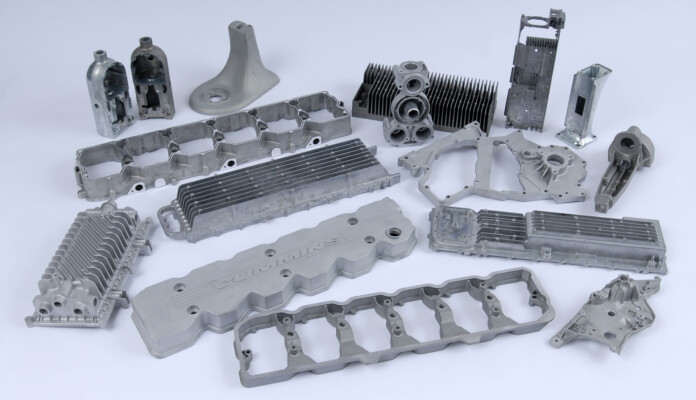

As supply chain reshoring continues to develop, there will be an increase in the number of opportunities for U.S. manufacturers in the form of supplier evaluations from new buyers. As a top U.S. die casting manufacturer and replacement tooling company, PHB Inc. is positioned to be an integral partner as more companies bring their business onshore. PHB is a one-stop shop for finished parts. PHB offers state-of-the-art die cast tooling and machining for contract manufacturers, including high-pressure injection molds for high-pressure valves, nuclear components, large gearing, and mechanical drives. PHB offers an array of in-house capabilities for a variety of applications:

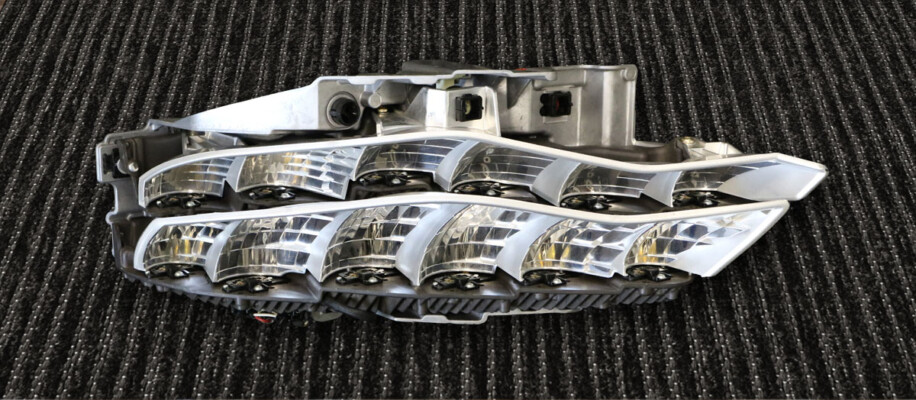

- Zinc and aluminum die castings – As a top U.S. die casting manufacturer, PHB produces zinc alloy die casting components for low and high-volume production programs and handles all aspects of aluminum die cast manufacturing.

- Machining – PHB offers close-tolerance CNC machining capability in turning, milling, drilling, boring, and tapping. Primarily an American die casting supplier, PHB also purchases and machines sand castings, cast iron, steel forgings, ductile iron, bar stock, and plastic.

- Leak testing – PHB offers in-house leak testing on a variety of products.>

- Assembly – PHB’s assembly includes brazing, leak testing, and helicoil insertion. They purchase components and manually assemble when required, shipping ready-to-use parts.

- Finishing – PHB manages customer finishing requirements, ensuring parts meet specifications in a timely and cost-effective manner.

- Rubber and plastic molding capabilities – PHB molding produces plastic and rubber overmolded products. They design parts for everything from upright mobility devices to finished parts on luxury automobiles. PHB provides the same secondary operations for these as they do for die castings.

PHB is an American Die Casting Supplier

Supply chain reshoring brings with it great opportunity and great need. There is an opportunity for American manufactures to become integrated into a growing number of supply chains. There will also be an increasing need for companies to find reliable and high-quality partners to supply parts and material.

American die casting supplier and replacement tooling company, PHB, Inc. offers solutions for companies searching for top U.S. die casting manufacturer partners.

Contact PHB for a quote or for more information.